Description

Electric and automatic hot steam-generator ESG-120SS

with heating capacity 87kW (120 kg of hot steam per hour), steam pressure from 2 bar up to 9 bar. Certificated for sterile pure steam – for direct contact with food and beverages. All parts which comes in contact with food are made of stainless steel. This level meets the standards EN 1672-2 and EN 285

This electric pure steam generator combines the most modern technical solutions used in this type of devices. All pressure elements in contact with feed water or clean steam are made of hygienic materials, mainly high-grade AISI 316L (1.4404) and AISI 316Ti (1.4571) stainless steel.

The high purity of the steam is also ensured by automatic desalination and desludging of the pressure system, and the design of the evaporator with a separating dome on top increases the dryness of the steam.

The software we have created to operate the device, diagnose the operating status, record the history of process parameters and the touch operator panel allow for quick and intuitive operation.

The materials and components of the highest quality used for the construction as well as the innovative design of the device ensure this model with very high reliability and low operating costs.

The ESG-120SS device is also characterized by very high aesthetics, and the structure and housing are made of high-quality AISI 304 (1.4301) stainless steel. This allows the device to be used in areas that require special hygiene.

The ESG-120SS Electric steam generator includes two innovative design solutions covered by patent protection.

The model ESG-120SS is certified by TUV Rheinland for compliance with standards EN 285 and EN 1672-2.

Made in EU

Recommended usage :

- Sterilization of kegs or bottles in using with machines designed to cleaning and filling of the kegs and bottles

- Sterilization of vessels, pipes, hoses and food equipment or farmacy equipment by hot steam

Technical parameters :

| Type | ESG-30SS | ESG-60SS | ESG-90SS | ESG-120SS | |

| Parameter | Unit | ||||

| Saturated steam output capacity | kg/h | 31 | 63 | 94 | 126 |

| Working pressure * (standard) | bar | 2.0 – 4.0 | 2.0 – 4.0 | 2.0 – 4.0 | 2.0 – 4.0 |

| Pressure on the safety valve * (standard) | bar | 5.0 | 5.0 | 5.0 | 5.0 |

| Working temperature * (standard) | °C | 5-152 | 5-152 | 5-152 | 5-152 |

| Maximal allowed temperature * (standard) | °C | 160 | 160 | 160 | 160 |

| Working pressure ** (optionally) | bar | 2.0 – 9.0 | 2.0 – 9.0 | 2.0 – 9.0 | 2.0 – 9.0 |

| Pressure on the safety valve ** (optionally) | bar | 10.0 | 10.0 | 10.0 | 10.0 |

| Working temperature ** (optionally) | °C | 5-180 | 5-180 | 5-180 | 5-180 |

| Maximal allowed temperature ** (optionally) | °C | 184 | 184 | 184 | 184 |

| Boiler capacity *** | liters | 26 | 26 | 61 | 61 |

| Heating power | kW | 21 | 42 | 63 | 84 |

| Number of work stages | 1 | 2 | 2 | 2 | |

| Power supply (connected load) | kW | 24 | 45 | 66 | 87 |

| Electric voltage supply | V | 400 3~ N+PE | 400 3~ N+PE | 400 3~ N+PE | 400 3~ N+PE |

| Dimensions and weight | |||||

| – length A / A1 ( ±10 mm ) | mm | 770 / 840 | 770 / 840 | 770 / 840 | 770 / 840 |

| – width B / B1 ( ±10 mm ) | mm | 840 / 850 | 840 / 850 | 940 / 950 | 940 / 950 |

| – height C / C1 ( ±10 mm ) | mm | 1550 / 1800 | 1550 / 1800 | 1600 / 1850 | 1600 / 1850 |

| Weight | kg | 230 | 250 | 270 | 300 |

Commentary :

* – Values are valid for the steam generator with the standard equipment – equipment is fitted and set to pressure selected from the range.

** – Values are valid for the steam generator with the optional equipment – change of settings require readjustment and/or replacement of some components. Will be priced individually for demand.

*** – Boiler capacity does not apply to the water supply reservoir capacity

Other parameters and accessories :

- All inner parts are made of stainless steel

- Stainless steel cabinet with the status display

- Made in accordance with standards EN 1672-2 and EN 285.

- Water inlet G 3/8″ male

- Steam outlet G 1/2″ male

- Gross weight (packaging included) 330 Kg

The main advantages of the ESG-120SS steam generator:

- high steam purity

- flexible performance

- easy and intuitive operation

- touch panel controller

- high durability of the device

- high quality components

- fully automatic operation

- mobility (transport wheels)

- ease and speed of assembly

- compact design

- small dimensions

- easy access to the interior of the cabinet

- solid and durable construction

Warranty : 12 months

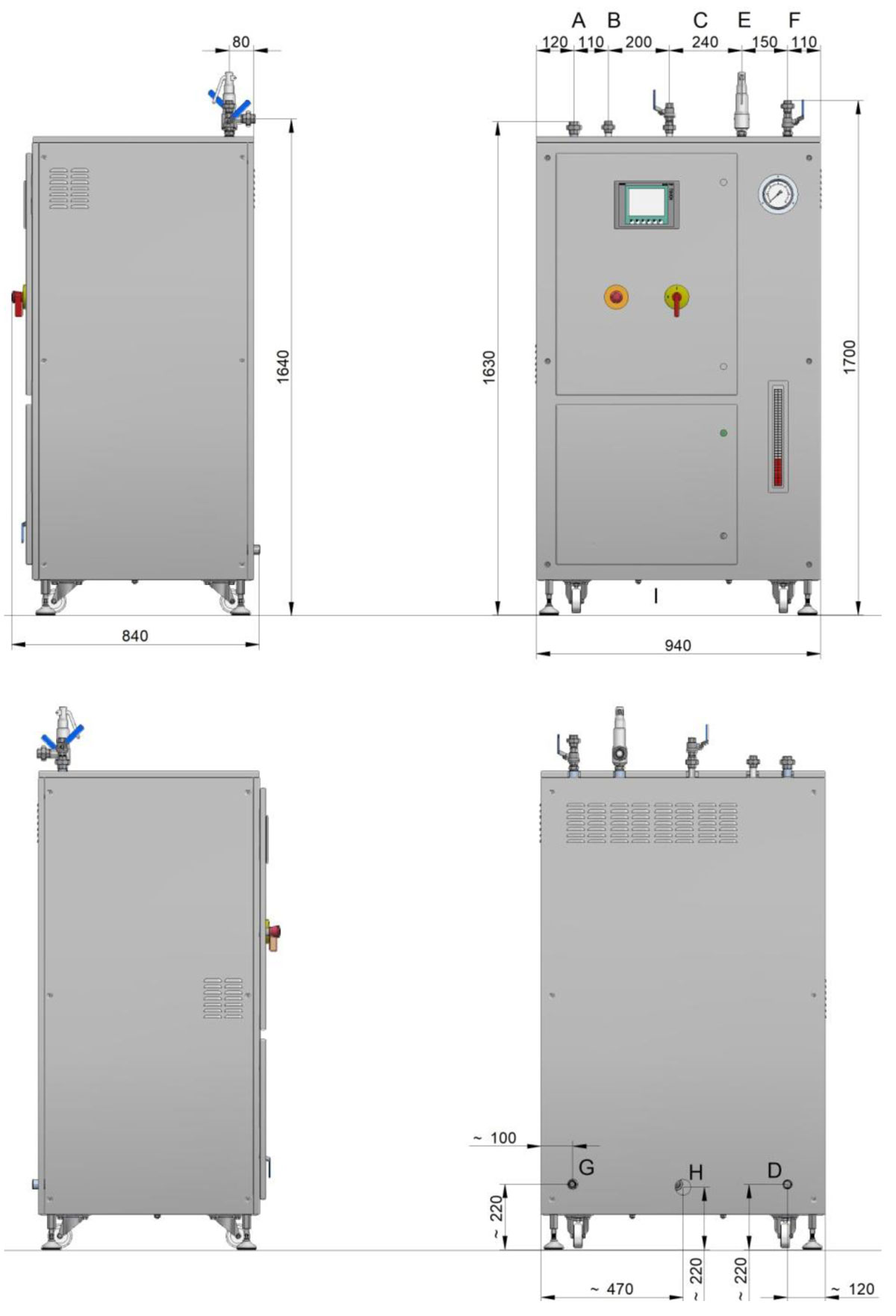

Dimensions and list of connections :

List of connections :

| Connector | Description | Connector type | Note |

| A | Tank vent | GZ ¾” | (pipe union) |

| B | Condensate return | GZ ½” | (pipe union) |

| C | Water inlet | GZ ½” | (pipe union) |

| D | Valve to desilting | GW ½” | (internal thread) |

| E | Safety overpressure valve | GW ½” | (pipe union) |

| F | Working steam valve | GW ½” | (pipe union) |

| G | Overflow and drain of tank | GW ¾” | (pipe union) |

| H | Electric supply | Terminal block | (connector on bus) |

| I | Earthing | M10 screw |

Optional accessories

| Description : | Price : |

| ESGSS-ADS : Automatic desilting system | On demand |

| ESGSS-DAT : Stainless steel cooling tank for desilting with aftercooling | On demand |

| ESGSS-WT120 : Water treatment system HONEYWELL / RESIDEO BRAUKMANN | On demand |

Delivery time :

Usualy 9-14 weeks after 1st payment

Payment conditions :

60% after ordering, 40% before delivery

Warranty :

12 months since delivery (does not apply to consumables such as heaters, contactors, valves …). The supplier reserves the right to assess each complaint individually. The complaint is filed at the place of the seller’s registered office.

Reviews

There are no reviews yet.