Description

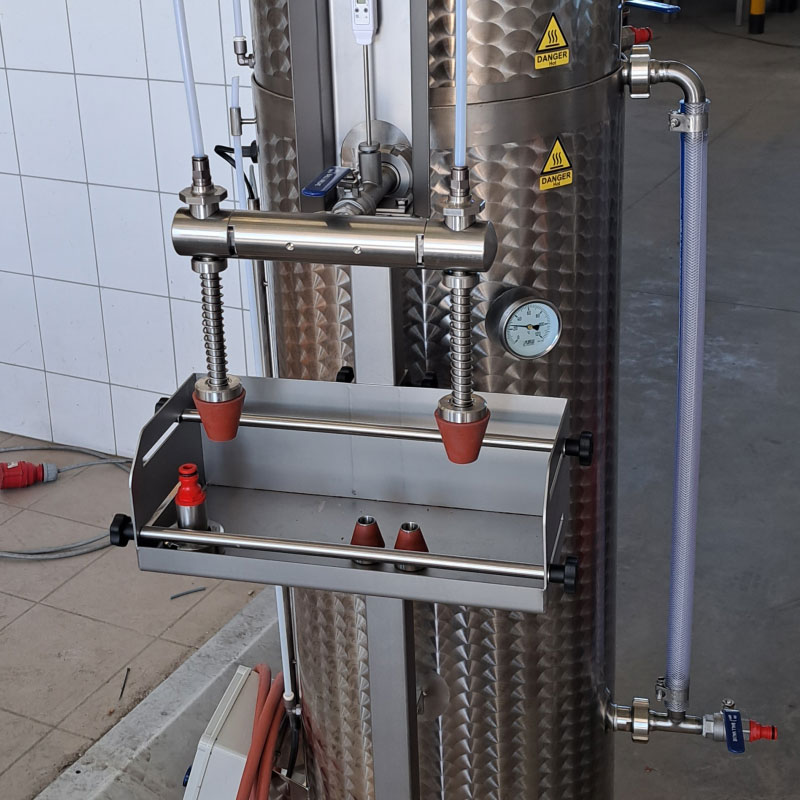

EPBBF-180MG is an automatic pasteuriser with integrated manual filling system of the BAG-IN-BOX or bottles. The pasteuriser is fully electric powered. It is designed to pasteurizing of non-carbonized beverages like juices, musts, sirups, and to their filling into BAG-IN-BOX packages. The system is not usable to work with beer, carbonized cider wine, sparkling wine or similar carbonizated beverages. Operation capacity from 180 liters per hour.

For heat treatment of different fruits juice (apple, pear, blackberry, strawberry, blueberry, elderberry, currant, carrot, herbs, quince, beetroot, sea buckthorn, rowan berries, onion) with built-in electric pasteurizer. Temperature check at two points, in the heat exchanger and once on the outlet. The machine automatically controls the heat exchanger temperature. It operates on a manual, gravitational principle. At the end of the work, the tube spiral can be cleaned very easily with the help of a sponge ball. It requires minimal maintenance.

Main features:

EPBBF-180MG : Flow-in pasteurizer with the automatic temperature control system :

- Capacity of 180 L / h (when heating from 20 ° C to 80 ° C)

- Electrical demands: 18 kW, 3-phase 400 V / 32A

- Heating power: 18 kW (2×9 kW electric heater)

- Material quality: WNr. 1.4301, AISI 304 Stainless steel

- Size: 600 x 1000 x 1750 mm

- Weight: 85 kg (without heating medium)

- Heat exchanger: soft water

- Beverage is in the tubular spiral which is heated by integrated electric heater

- All parts in contact with a beverage are made of stainless steel AISI 304

- As the heater is integrated in the boiler this means saving of space

- Saving of heating energy by up to 15-20%.

- Heating medium: water (soft)

- IP65 rated electronics

- Connectors: DN25 hollander

- Temperature is checked at 2 points, in the heating medium and once on the outlet of the product

- The machine automatically regulates both the heating medium and the product temperature with a built-in by-pass valve and pump.

- Temperature control is automatic.

- Filling process is manual

- Integrated a simple manual filling system of the BAG-IN-BOX

- Requires minimal maintenance

- Upper buffer tank with level switches (optional equipment according to client´s needs)

- Easy to clean with sponge balls

- Requires minimal maintenance

- Adjustable machine feet

Pasteurization parameters :

- Maximal volume of carbodioxide CO2: 0 g/liter (usable only for non-carbonized beverages)

- Maximal flow speed of beverage: 180 liters/hr

Accessories :

- Manual Bag In Box filler with the digital scale

- Sponge balls for cleaning

Options:

| Code | Photo | Description | Price |

| EP-MBF-180 |  |

Manual bottle filling unit | in price |

| EP-BBF-180 |  |

Manual BIB filling unit | in price |

| EP-MBF-180 + EP-BBF-180 | Both manual filling units (replaceable each other) | € 1130,- | |

| FFV-HP034 |  |

Float filling valve stainless steel, connection G3/4

This valve allows the automatic filling juice into the buffer tank from an external source tank. Feeding juice from the external tank must be ensured by a pump or gravity (the source tank is placed higher than the pasteurizer). |

€ 199,- |

One type of the filling modules is inclued in basic price – by choice of a customer.

Delivery time :

- Usual delivery time is 30-60 days from first payment.

Dimensons for transport :

Standard wooden europallet 800 x 1200 x 1700 / 110 kg

Warranty time :

- 12 months

Reviews

There are no reviews yet.