Description

The BFL-KT2200 is an automatic rotary bottle filling line with built-in bottle closure unit. Designed only for non-carbonated beverages. Capacity up to 2200 bottles per hour.

Designed for filling wine, fruit juices and other non-carbonated beverages into glass bottles. The bottles are automatically transported into the machine and are automaticall filled, after which they are automatically closed with a crown cap, cork or screw cap – depending on the installed closure unit type. 16 filling heads included.

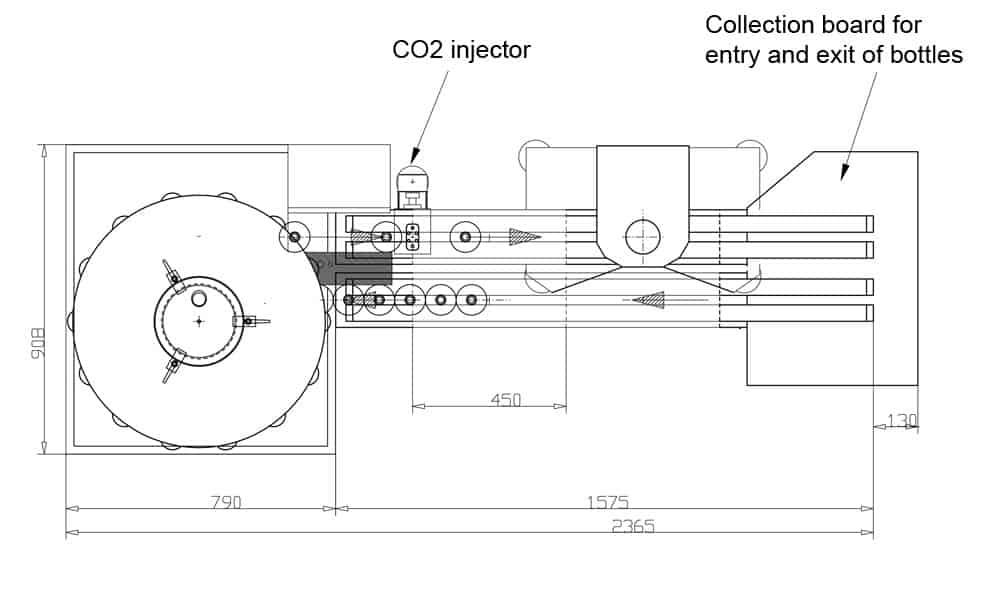

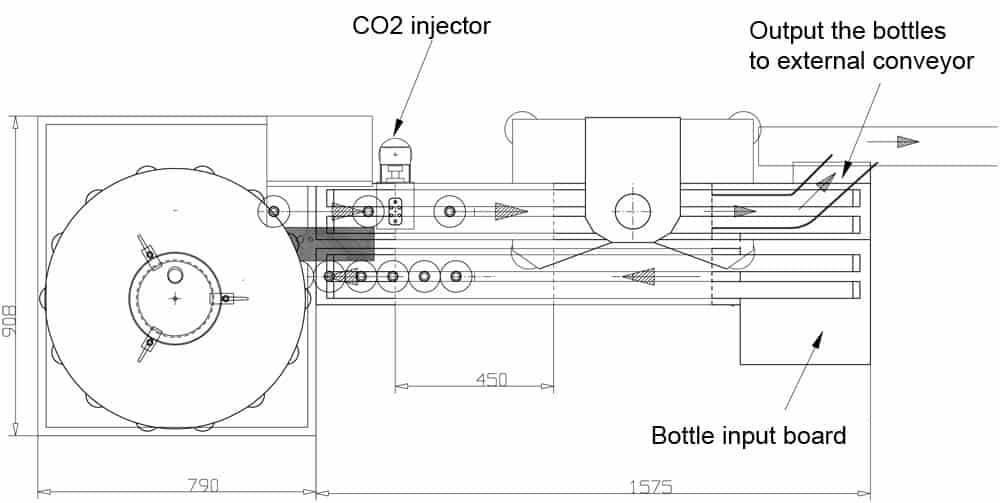

Dimensions and floor plan:

1. Standard compact version

2. Version with output the bottles to an external conveyor

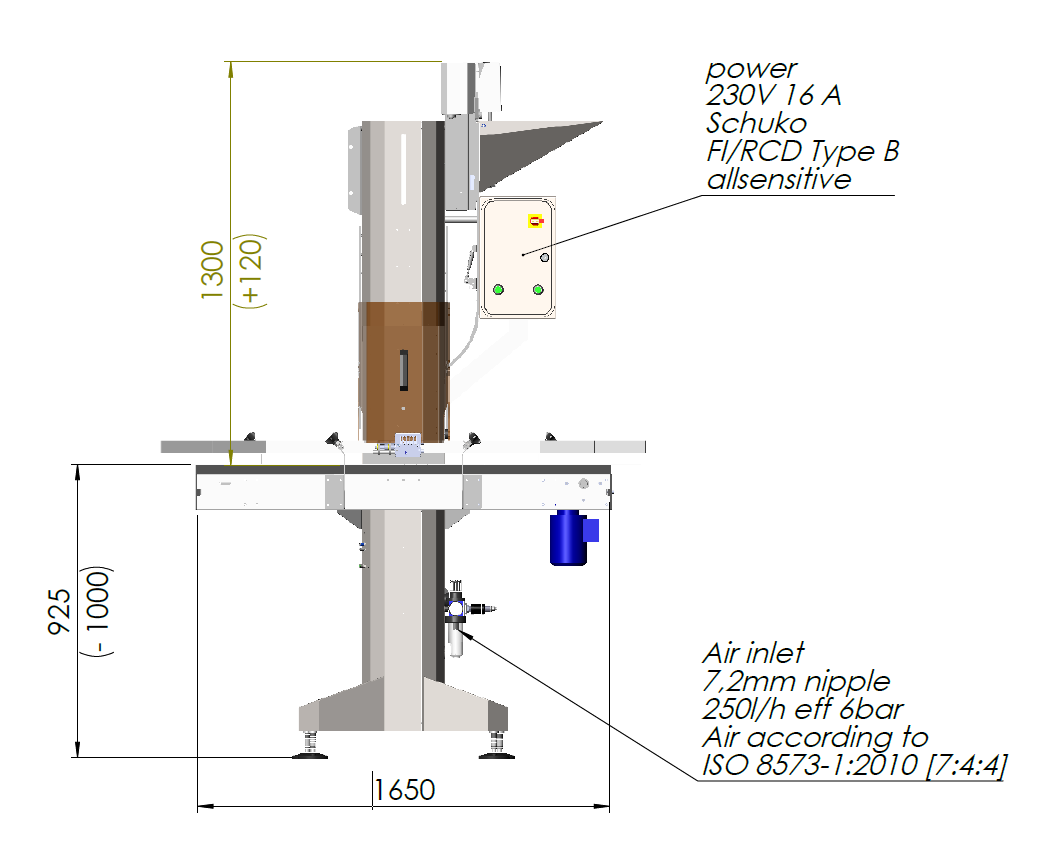

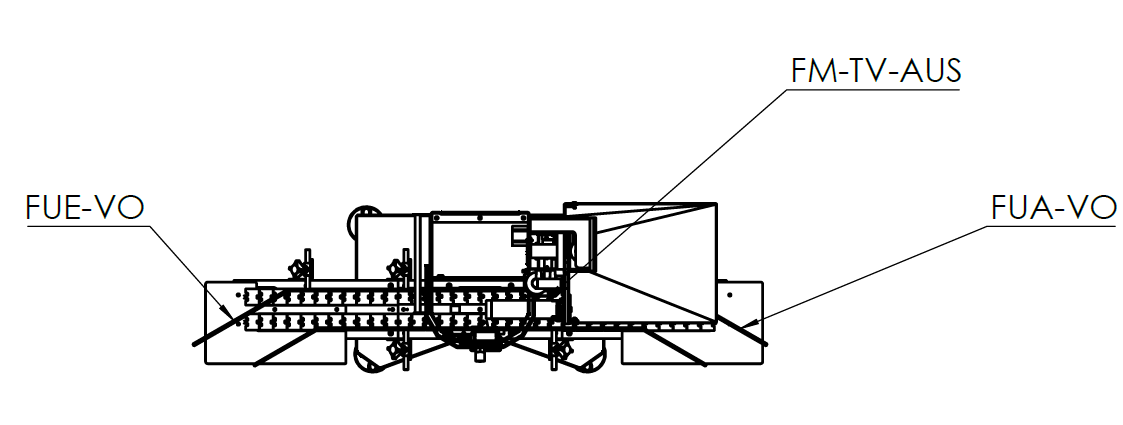

Bottle conveyor (input-output) :

Hight of the bottle conveyor is adaptable between 925mm and 1000mm.

Technical specification:

| Type | BFL-KT1600 | BFL-KT2000 | BFL-KT2200 |

| Electrical connection | 230VAC | 230VAC | 230VAC |

| Dimensions (LxWxH) [mm] |

2500x900x2500 | 2500x900x2500 | 2500x900x2500 |

| Weight [kg] | 400 | 420 | 420 |

| Filling valves | 10 | 14 | 16 |

| Output capacity (max) [bottles/h] | 1600 | 2000 | 2200 |

| Tank volume [l] | 90 | 200 | 200 |

| Bottle diameter [mm] | 55-120 | 55-120 | 55-120 |

| Bottle height [mm] | 160-400 | 160-400 | 160-400 |

| Effective air consumption [l/min] | 200 | 200 | 200 |

Features :

Features :

- Full automatic

- 16 filling heads on the rotatable station

- One reception star wheel for bottles Ø76-90 (after choice) is included

- With the conveyor (3000m long), sorter, fall channel, cap dispenser

- Buffer tank with electrical height adjustment

- Bottle stopper with integrated bottle detection

- Easy switching between crown capper, corker and screw capper in just 5 minutes!

- Easy switching between different bottle sizes

- Stepless adjustable filling level of the bottles

- Stepless adjustable speed of the filling unit

- Also suitable for non-pressurized beer (before in-bottle secondary fermentation) and hot fruit juices

- Suitable for steam sterilization, easy to clean

- Automatic safety stop in case of blockage

- 1 closure head included (for steel crown caps, cork stoppers or screw caps)

Available accessories:

- Special closure heads (for steel crown caps, cork stoppers or screw caps).

- Collection desk for input and output the bottles.

- Bottle conveyor 1.5 m at the exit with nylon rolls.

- Electric conveyor at the exit (speed adjustable from 2 till 12 m/minute), with the collection desk 50 x 60 cm.

- Jam reporting sensors with automatic switch-off function

- CO² interaction and level regulation.

- Filling level monitor for the buffer tank.

- Bottle pre-evacuation with inert gas injection.

- Crown head for 26 and 29 mm crowncaps

- Electrical level control with 2 switching points (empty and full).

- Sterile cartridge filter for air supply tank.

- Stainless steel wheels.

- Three-sided protection shield with safety doors.

- Transport and lifting frame for the whole system.

- Add-on kit for filling bottles with hot liquids.

Prices of recommended accessories :

| … for type |

BFL-KT1600 | BFL-KT2000 | BFL-KT2200 |

| Reception stars for bottles Ø 68 – Ø90 | 10x € 563 | 14x € 613 | 16x € 656 |

| CIP unit to clean the filling valves | € 1088 | € 1213 | € 1338 |

| CO² interaction and level regulation | € 1908 | € 1908 | € 1908 |

| Closing unit for steel crown caps Ø 29 | € 1032 | € 1032 | € 1032 |

| Bottle detector at exit to detect bottle jams | € 348 | € 348 | € 348 |

| Output the bottles to an external conveyor | € 168 | € 168 | € 168 |

| Transport and lifting frame (needed for transport to a customer) | € 990 | € 990 | € 990 |

| Rotable stainless steel wheels | € 600 / pc | € 600 / pc | € 600 / pc |

| Shoes for the fork lift | € 216 / pc | € 216 / pc | € 216 / pc |

Installation and commissioning

Price includes only the filling line without related services.

We recommend to order the installation and commissioning ensured by our specialists. Prices of the install services is 500 Eur per day + transport and accomodation costs.

Reviews

There are no reviews yet.