Description

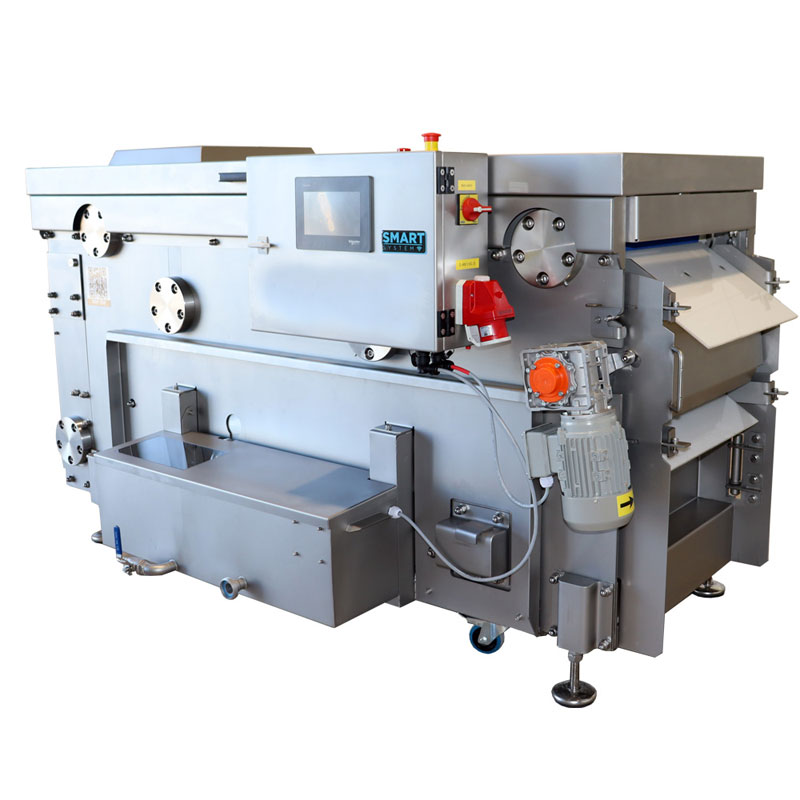

The single belt press FBP-700MG is designed for pressing of fruit mass. Fruit mass is placed on the continuous belt which presses it against cylinders. The obtained juice flows in the collection trays under the press. Production capacity up to 700 kg of fruit per hour.

Main properties and demands :

- Entirely made of stainless steel AISI 304 / 1.4301

- Continual pressing process.

- Yield up to 75% (depending on the kind, freshness and quality of the fruits)

- Low oxidation and high quality of must and cider

- Pressing of fruit with a gradual increase of pressure

- Integrated juice collection buffer tank with the pump for automatic transport of pressed juice to an external tank

- Variable speed of the belt

- IP65 certified electronics

- Food industrial, massive polyester belt – 2mm thick, density: 6×16 filament/cm2, ½ rate (suitable for large fiber-free juice)

- High-pressure washer demand: 360 L/h

- Compressed air demand: 50 L/h 6 bar

- Built-in inverter: steplessly adjustable belt speed

- Fully automatic operation, with closed work area, reduces the fruit mash oxidation to the minimum.

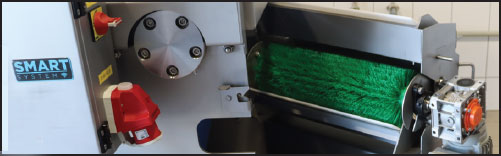

- In the bottom of the machine, there are two spinning washer heads guarantees optimal cleaning during the process.

- The distance between the press cylinder and the juice collector tray is reduced to avoid the fruit juice foaming.

- The belt press can be disassembled without any tools in few minutes!

- Very easy to clean.

- With 4pcs of the adjustable vibration-free feet.

- Requires minimal maintenance.

- Both an external high-pressure washer and air compressor are essential for operating.

Main advantages of this new model :

Closed section frame changed for steel plate frame

Most robust bearing housing on the market

The brush cleaning module with the dry waste scrapers can be also opened, since the module is connected to the frame on hinges.

The entire juice collector tank, along with the belt washer unit, can be rolled out on wheels, making it easy to clean

Automatic collector tank and level sensors are built in

Mash guides made from more resistable danamid material instead of plexi sheets

The machine can be disassembled to the frame without tools in 2 minutes

Built-in Schneider PLC panel with the following functions:

• working hour counter

• belt controls – speed and direction

• brush controls

• error log

• notifications for the operator about maintenance according to the working hours

Technical parameters :

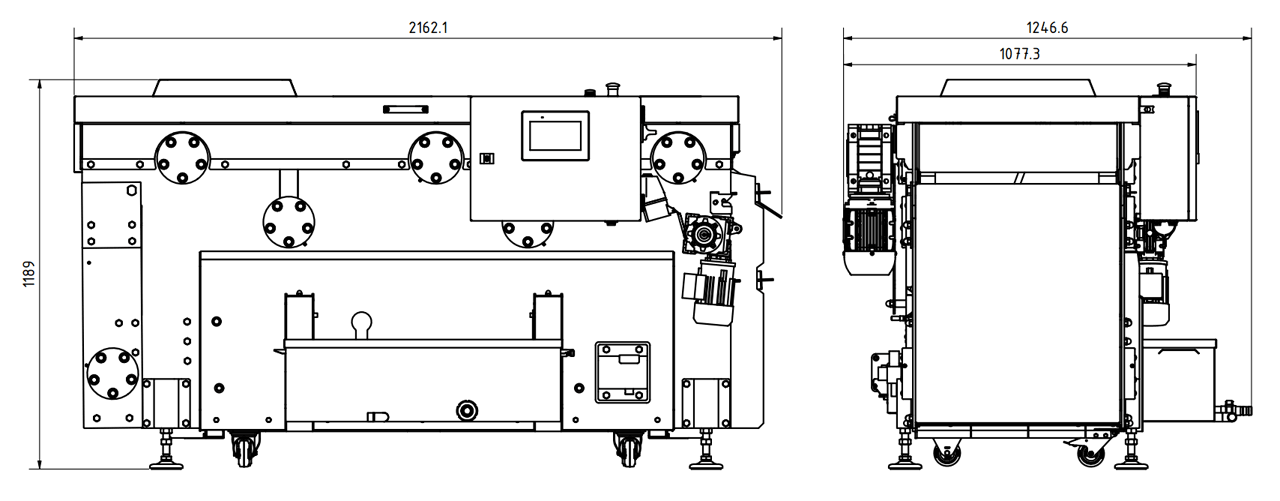

| Length | 2200 mm |

| Width | 1280 mm |

| Height | 1180 mm |

| Belt width / thickness | 600 mm / 2 mm |

| Weight | 890 kg |

| Connected power | 1.5 kW / 6A |

| Electric demands | 3-phase ~ 400V 50 Hz (6A) |

| Material | WNr. 1.4301, AISI 304 stainless steel |

| Capacity | 700 kg/h (it depends on the kind, freshness and quality of the fruits) |

| Yield (efficiency) – dependent on a variety of apples and pressing time (fall, winter, spring) | up to 75% (it depends on the kind, freshness and quality of the fruits) |

| Noise emission level | 60-70 dB |

Hose connections on the machine :

| Description (purpose) | Hose connection on the machine | Intended for |

| High pressure water (to cleaning the belt) | Nilfisk quick coupler male or M22x1.5 thread male | Nilfisk quick coupler female or other quick coupler with M22x1.5 thread female |

| Pressure air inlet (6 bar) | Quick hose coupler for pressure air 1/2″ male | Hose 3/4″ with the quick hose coupler for pressure air 1/2″ female |

Optional equipment and spare parts : |

||

| Code | Description | Price |

| SBP-DPS | Different power supply (Voltage / Frequency) | € 300,- |

| SBP-ECL | Electrical cabinet on the left side (In standard version it is on the right side) | € 100,- |

| SBP-FRI | Frequency inverter (for variable speed of the belt motor) | Included in price |

| FSC-JCT | Automatic juice collector tank with the pump | Included in price |

| SBP-BLT | Spare belt | € 750,- |

| FSC-PRR | Spare press roller | € 690,- |

| FSC-CRR | Spare correction roller | € 690,- |

| FSC-RBR | Spare rubber roller | € 890,- |

| FSC-BSW | Spare bushing set for belt washer | € 22,- |

| FSC-REA | Remote access (internet connection is needed) | On demand |

| FSC-AKN | Air-knife instead of high pressure water belt cleaning for zero water consumption | On demand |

Reviews

There are no reviews yet.