Description

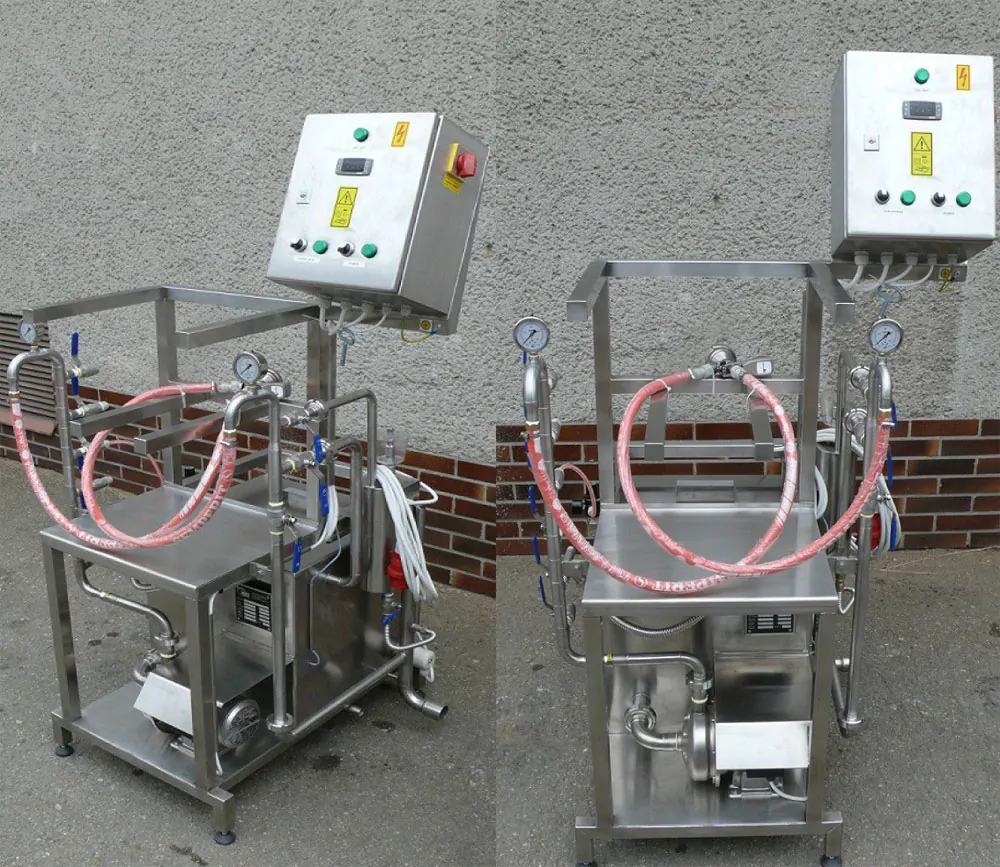

The KCM-10 is a multifunction machine that includes a device for rinsing of stainless steel kegs and the filling of carbonizated beverages like beer, lemonade wine or cider, into kegs. The equipment is designed for the filling and rinsing of kegs with beer, cider, wine and for other beverages, using manually operated valves and a pump.

Operating capacity : seven – ten kegs per hour (rinsing and sanitizing cycles / filling cycle).

The machine is designed for cleaning and filling kegs with a volume from 15 to 50 liters. The working performance is :

- Two cycles : the rinsing cycle & the sanitation cycle : the maximal performance 10 kegs per hour ( with volume of 50 liters).

- Three cycles : the rinsing cycle & the sanitation cycle & the filling cycle : the maximal performance 7 kegs per hour ( with volume of 50 liters).

The actual capacity of the machine depends on how dirty the kegs are and how long time it has been since they were used. For more dirty kegs, it is necessary to set longer times for individual washing cycles and this reduces the capacity in the number of kegs per hour. If the drink foams more, the time required to fill the kegs also increases (in this case, we recommend lowering the temperature of the drink in the source tank).

Inserting of kegs is manual, removing of kegs after finalizing of filling cycle is manual. Operator manually opens and closes all valves, switches on the pump and controls a temperature of the sanitizing solution manually as well. The machine is equipped with an integrated reservoir for the alcalic sanitizing solution.

Sterilized compressed air is needed for flushing inner space of the keg, which can contain of the rest of water or sanitizing solutions.

We recomment to use an external hot steam-generator as optional accessories to ensuring perfect sterilization of the inner walls of the kegs and shorter cleaning and sanitation cycle.

Material is stainless steel AISI 304.

The device operates in the following cycles:

- An emptying the keg

- A depressurization the keg

- Flushing the keg with cold water

- Flushing the keg with sanitizing solution

- Flushing the keg with hot water

- Steam sterilization of inside of the keg (requires external source of steam)

- Filling the keg with carbon dioxide gas

- Filling the keg with beer

All cycles 1-8 run manually.

Sterilized compressed air is needed for flushing inner space of the keg, which can contain of the rest of water or sanitizing solutions.

We recomment to use an external hot steam-generator as optional accessories to ensuring perfect sterilization of the inner walls of the barrels and shorter cleaning and sanitation cycle.

Description of the keg rinsing and filling process step by step:

1. All valves are closed

2. Connect the filling coupler on the keg

3. Overturn the keg and place it on the KCM-10 unit

4. Open valve 1.8 (waste) and valve 1.2 (air). The rest of content in the keg is drained.

5. Valve 1.8 (waste) remains opened, close valve 1.2 (air) and open valve 1.4 (cold water).

That is the first rinse of the keg. Time of rinse will vary depending on total volume and degree of pollution of the keg.

6. Close valve 1.4 (cold water), valve 1.8 (waste) remains open.

7. Valve 1.8 (waste) remains open, open valve 1.2 (air). Water is forced out of the keg by air. Time may vary depending on the total volume of keg.

8. Close all valves. Open valve 1.7 (caustic), turn on the pump. The caustic sanitation of keg is in progress. Time may vary depending on the total volume of keg. The valve 1.2 (air) may be opened to improve the scattering of sanitation solution.

9. Turn off the pump and open valve 1.2 (air). Cycle of returning the caustic to caustic tank runs.

10. Close all valves.

11. Open valve 1.8 (waste), open valve 1.3 (hot water). Rinse until the keg is completely deprived of caustic (usage of pH meter is recomended). The valve 1.2 (air) may be opened to improve the scattering of hot water.

12. Close valve 1.3 (hot water), valve 1.8 (waste) remains open, open valve 1.2 (air). Hot water is forced out of the keg by air. Time may vary depending on the total volume of keg.

13. Close all valves. Open valve 1.1 (CO2) and open valve 1.8 (waste). Air is forced out of the keg by CO2 gas. Time may vary depending on the total volume of keg.

14. Close valve 1.8 (waste), valve 1.1 (CO2) remains open. Fill the keg with CO2 until the inner pressure is 1.8 bar. The inner pressure is controlled by pressure regulator.

15. Close all valves.

16. Put the keg on the floor, open valve 1.6 (beer) and open valve 1.9 (outlet of CO2 from keg). Keg is being filled by beer, filling speed is controlled by pressure regulator. When he beer foam starts flowing from pressure regulator, the keg is full.

17. Keg is sanitized now, filled with beer and ready to be shipped to your customer.

Filling of the 50L beer keg takes from 1 to 4 minutes – the time depends on the chosen overpressure in the keg and in the beer storage tank, temperature of beer, beer type and other physic influences.

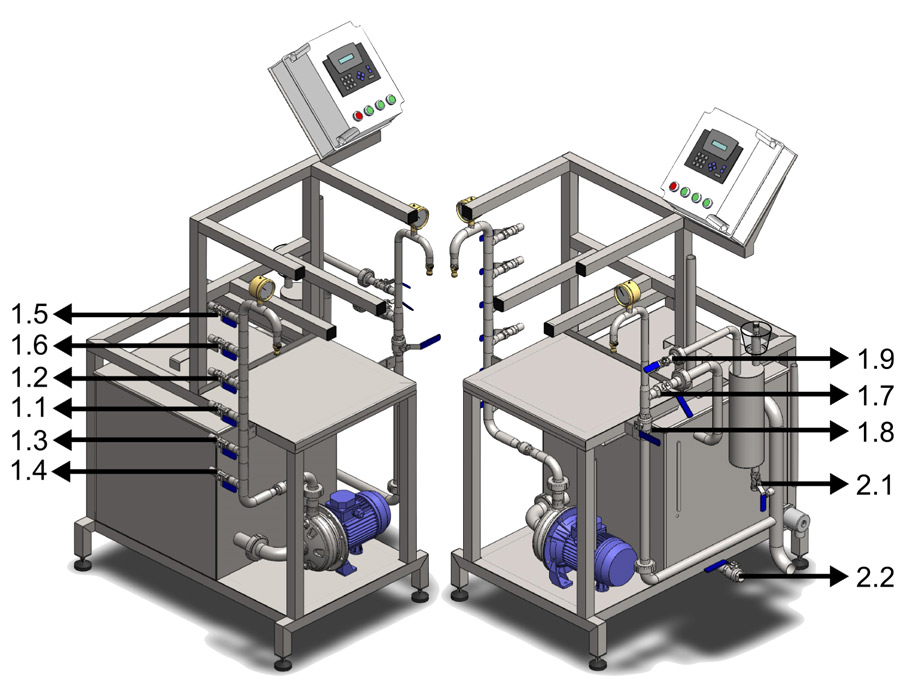

KCM-10 Keg cleaning and filling machine – Technical description:

Valves :

1.1: CO2 input (inert gas)

1.2: Compressed air input (blowing out of beer rests from the keg)

1.3: Hot water input (warm rinsing)

1.4: Cold water input (cold rinsing)

1.5: Hot steam input (optionally for more efficient sterilization)

1.6: Beer input

1.7: Caustic solution input

1.8: Waste pipe output (dirty water)

1.9: Outlet of CO2 from the keg

2.1: Outlet of overflow beer if the keg is full

2.2: Outlet of used caustic solution

Technical parameters :

| Material | AISI 304 |

| Maximum performance : rinsing & sanitation | 10 |

| Maximum performance : rinsing & sanitation & filling | 7 |

| Volume of kegs maximum [ liters ] | 50 |

| Inserting and removing kegs | manually |

| Electrical connection | 3F 400V /50Hz 16A |

| Heating | 2x 2.2 kW |

| Pump | 750 W |

| Control panel | 230V / 50Hz |

| Switching between modes : washing – filling | manually |

| Sterilisation mode with hot steam (optionally) | external hot steam-generator |

| Width / mm / | 1200 |

| Depth / mm / | 800 |

| Height / mm / | 1900 |

| Weight /kg/ | 130 |

| Average delivery time / months / (after first advance payment) | 2 |

Media and connections :

Connections to pipelines :

- Steam – thread G1/2″

- Beer – thread G1/2″ / hose 12/7×9.5mm

- CO2 – thread G1/2″ / hose 12/7×9.5mm

- Compressed air – thread G1/2″ / hose 9.5×6.7mm

- Hot water – thread G1/2″ / hose 12/7×9.5mm

- Cold water – thread G1/2″ / hose 12/7×9.5mm

The connection to the pipelines can only be carried out by persons who are familiar with the properties and function of the pressure vessel and are also familiar with the relevant regulations for its operation

Input media

- Hot steam

- minimum pressure 3 bar

- maximum pressure 5 bar

- maximum temperature 160°C

Cold water

- minimum pressure 2,5 bar

- maximum pressure 4 bar

- recommended temperature 8-12°C

Hot water

- minimum pressure 2,5 bar

- maximum pressure 4 bar

- recommended temperature 80°C

Pressure air

- minimum pressure 6 bar

- maximum pressure 8 bar

- must not be contaminated by

– humidity – dry air

– solid particles (oil)

– microorganisms (sterility) - (Only oil-free air compressor with very fine air filtration and air dryer can be uses … see recommended air compressor and filtration bellow)

Carbon dioxide CO2

- recommended pressure : from 0.5 bar up to 1.0 bar

(From the pressure bottle with carbon dioxide)

Beverage product

- Beer, cider, wine, juice, lemonade etc (beverage to be filled into kegs)

- minimum pressure 2 bar

- maximum pressure 3 bar

Sanitizing chemical solution :

- As a sanitizing solution, we recommend using a NaOH alkalic solution with a maximum concentration of 3%

- The total volume of the tank is 150 l

- The filling volume is 125 liters – calculate the concentration on this volume (in the factory settings, the heating temperature of the sanitation solution is set to 60°C, if necessary, this value can be changed in the control application settings)

Electrical connection

- Power supply 3+PEN, 50Hz, 400V, TN-S

- Installed input power 4.7kVA

- Control voltage 24 VDC

- The filling unit is fitted with a CYKY5x2.5 connection cable in length 5m, the end of a plug socket 400V 16A

- The connection to the electrical network can only be carried out by persons who are familiar with the characteristics and function of the pressure vessel and are also familiar with the relevant regulations for its operation

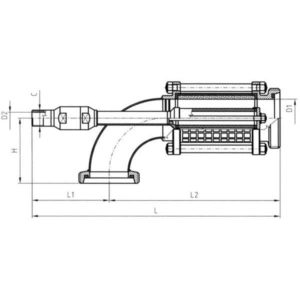

Available keg couplers – the filling heads :

That’s how the filling valve looks – all types A, D, G, M, S, U are available according to requirement of the customer :

Recommended set of spare parts … price € 1200,-

The set includes :

- 2 pcs x electric heating spiral …. € 82,- / pc

- 2 pcs x gasket for EBARA CDX pump … € 120,- / pc

- 1 pc x pneumatic valve …. € 270,- / pc

- 2 sets x hoses and couplings …. € 120,- / set

- 2 sets x filling head for kegs …. € 140,- / set

Recommended accessories :

ESG-7MWT : Electric steam-generator compact 7kg/hr (on the stainless steel frame, with water treatment)

Electric and automatic steam-generator, available power 3.5 kW. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is 3.5 bar. The steam-generator shell is manufactured in accordance to the current PED regulations. The water treatment system (for automatic water softening) and electric switchboard cabinet is included in this set. All system is mounted on the stainless steam frame. Easy installation – without electrician works – it is needed only to plug on the electric power socket on the wall.

ACO-350-200OF : Oil-free air compressor 21.0 m3/h (350 l/min) with pressure tank 200 liters

Since air is also used in the individual steps of sanitation, it is necessary that this air be sterile, free of moisture and not contain any residues of solid particles or oils that have escaped into the air distribution system from the compressor.

Piston air compressor of the oil-free Pro Line Zero series. Machine output 350 l/min (21.0 m3/h) at 3 kW, power supply 3-phase 400V/50Hz. Compact lightweight oil-free piston air compressor with direct drive with a maximum air pressure of 10 bar and an air pressure tank with a volume of 200 liters. Automatic run control using Condor’s superior pressure switch. Minimal machine maintenance.

AFS6-B700-38F : Extended 6-stage sterile air filtration set 0.005 µm FUTURA – 300 L/min (3/8″)

6-stage air filtration set FUTURA 1/4″ with maximal capacity of 300 liters per minute. Recommended air filtration set to use in the food industry.

The set consists of these air filters :

- AF-DF1038 : Dust filter 1000 l/min (3/8″)

- AD-RDL3512F : OMEGA Air Dryer – 583 l/min (1/2″)

- AF-FV14F : Air prefilter 0.3 µm FUTURA – 2200 L/min (1/4″)

- AF-FX14F : Air microfilter 0.01 µm FUTURA – 300 L/min (1/4″)

- AF-FA14F : Air filter with active carbon 0.005 µm FUTURA – 700 L/min (1/4″)

- AF-DF1038 : Dust filter 1000 l/min (3/8″)