Description

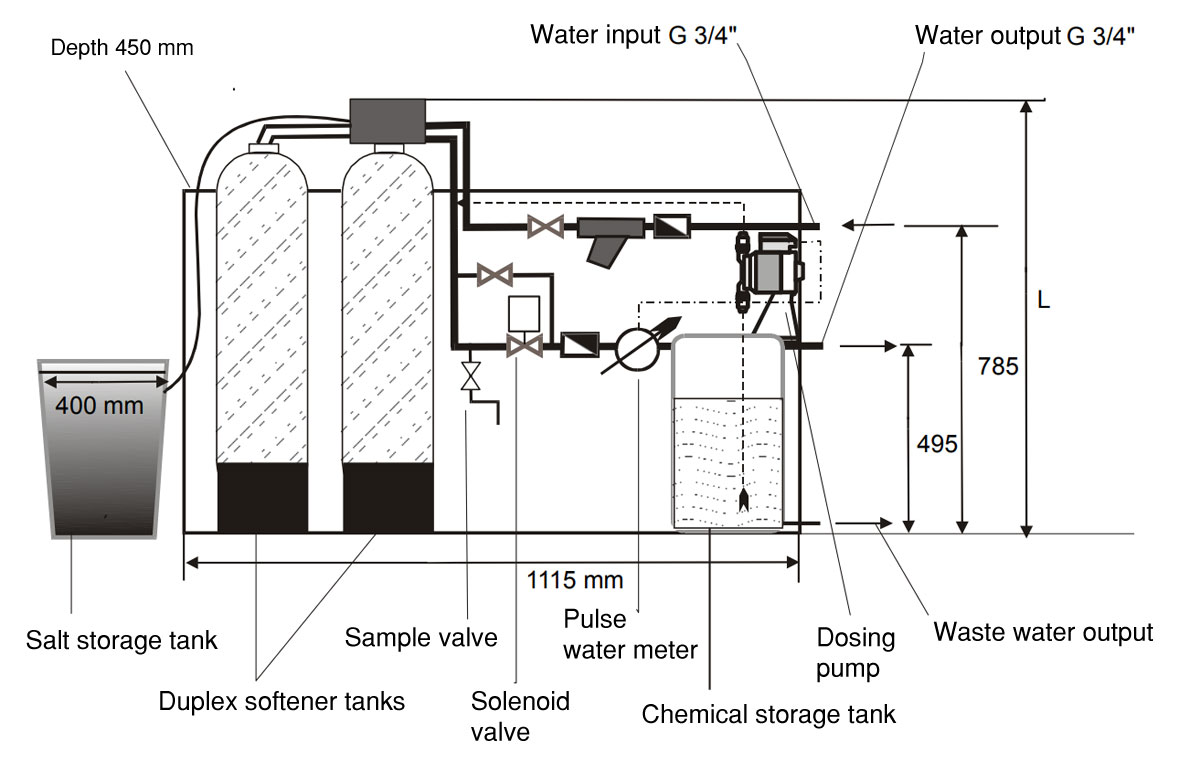

Automatic duplex water treatment system with a dosing pump designed for use with steam generators with capacity up to 2500 kg of steam per hour

The automatic block water treatment plant with capacity up to 2500 liters per hour meets the requirements for the operation of boiler rooms with steam generators with occasional service and guarantees the supply of high-quality treated water to the system according to ČSN 07 7401. The output of treated water from the water treatment plant is under water line pressure. An additional pump with an interruption tank (domestic waterwork) must be used in a heating system with a higher operating pressure.

Water replenishment into the system can be started either manually or automatically depending on the level of the measurement and control system.

The water treatment plant is equipped with a duplex automatic softener and a dosing unit for corrective mixed chemicals from the storage tank.

The control unit of the double water softener automatically switches the operation to the second one when the capacity of the first filter is exhausted, while the first one regenerates, and thus the automatic water treatment plant is able to treat the water continuously. The task of the operator is only occasional addition of regenerating salt and chemicals to the tanks. At the moment of refilling the system, the exact amount of mixed chemical from the plastic container is dosed into the flowing softened water by the electromagnetic diaphragm pump. The mixed chemical ensures the correction of pH, alkalinity, deoxygenation of water and maintenance of the required excess of phosphates.

Water inlet and outlet with G 3/4 “thread are located when viewed from the front on the right side of the water treatment plant from the side. The horizontal distance of the inlet axis from the rear edge of the device is 50 mm, outlet 300 mm.

The water treatment plant is supplied equipped with a salt tank and a primary charge of regenerating salt and mixed chemicals.

Required installations:

- Water supply G 3/4 “

- Waste water with a density of at least 4 m3 / hour.

- Electrical socket 1-phase 230V, 50 Hz

| Technical parameters | WTS-SG3 | WTS-SG6 | WTS-SG13 | WTS-SG25 | |

| Feed water pressure | MPa | 0.2 – 0.6 | 0.2 – 0.6 | 0.2 – 0.6 | 0.2 – 0.6 |

| Maximum working temperature | °C | 40 | 40 | 40 | 40 |

| Power supply voltage and frequency (1 phase) | V / Hz | 230 / 50 | 230 / 50 | 230 / 50 | 230 / 50 |

| Nominal flow capacity | L/h | 320 | 680 | 1320 | 2500 |

| Maximum flow capacity | L/h | 2000 | 2000 | 2500 | 3000 |

| Softening resin filling volume | L | 2×11 | 2×17 | 2×40 | 2×68 |

| Capacity of one bottle | mol | 6.6 | 10.2 | 24.0 | 40.8 |

| NaCl consumption per 1 regeneration | kg | 1.6 | 3.4 | 6.6 | 15.8 |

| Width | mm | 960 | 1050 | 1150 | 1300 |

| Depth | mm | 650 | 650 | 650 | 650 |

| Inlet connection height | mm | 850 | 850 | 850 | 1230 |

| Output connection height | mm | 580 | 580 | 580 | 950 |

| Height | mm | 1060 | 1060 | 1180 | 1550 |

| Weight | kg | 50 | 68 | 96 | 176 |

Scheme of the water treatment system

Reviews

There are no reviews yet.