Description

JESSBERGER JP810.170 Pneumatic stainless steel diaphragm pump for feedeng beer or cider to the filler, hop extractor or other equipment for product finishing. This device works without electrical consumption – it needs only pressure air and a pressure reduction valve. Minimalized mechanical impact on beer. Pump volume power : 110 – 170 liters / min. (6.6-10.2 m3 / hour). Liquid connection DIN 32676, Tri-Clamp DN40 1 1/2″, Air connection 1/2″ BSP.

This pump is certificated for use with food processing – ATEST EN 1935/2004.

STANDARD:

II 3/3 GD C IIB T135 °C (EX ZONE 2)

CONDUCTIVE:

II 2/2 GD C IIB T135 °C (EX ZONE 1)

Due to the material used (stainless steel, electropolished), the Food series can be used for many applications in the pharmaceutical and food industry.

Parameters :

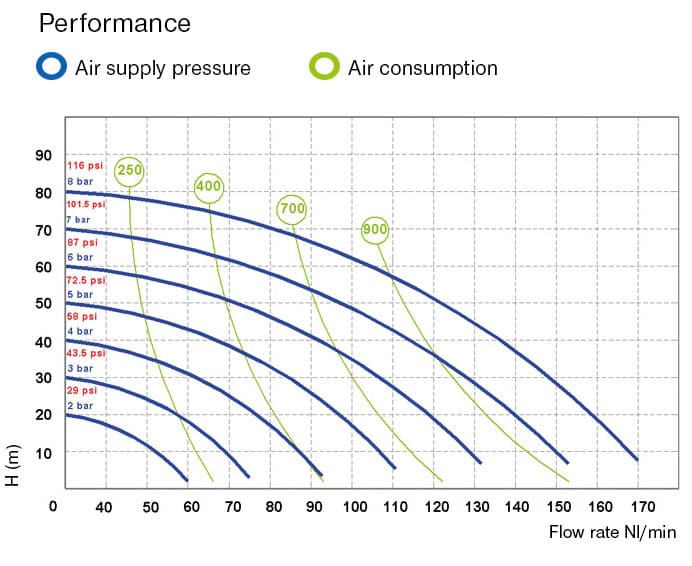

Pump volume power : 110 – 170 liters / min. (6.60 – 10.20 m3 / hour)

Air pressure : 5-8 bar

Weight : 20 kg

Delivery head : 80 m

Suction lift dry : 6.0 m

Suction lift wet : 9.8 m

Temperature : -20°C up to 95°C

Max. particle size : 7.5 mm

Max. viscozity : 35000 mPas

Noise level : 75 dB

No electric connection – the pump is fully powered by pressed air

Material :

Fluid section, air section : Stainless Steel AISI 316, Ra=3.2 μm

Casing : Stainless Steel AISI 316 / Electro-polished

Valve seat : Stainless Steel AISI 316

Check valve ball : T=PTFE / S=Stainless Steel AISI 316

Diaphragm membrane : 2x HT=HYTREL+PTFE

Gaskets : T=PTFE

Fluid connections :

Liquid : DIN 32676, Tri-Clamp DN40 1 1/2″

Pressure air : 1/2″ BSP

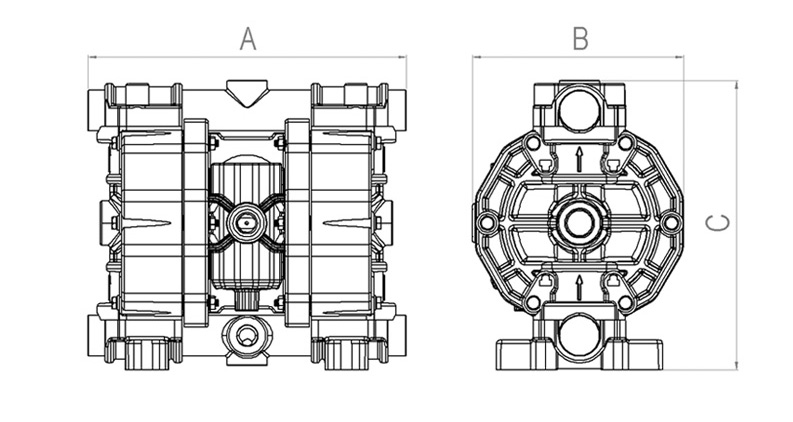

Dimensions :

A : 360 mm

B : 222 mm

C : 346 mm

Weight : 20 kg

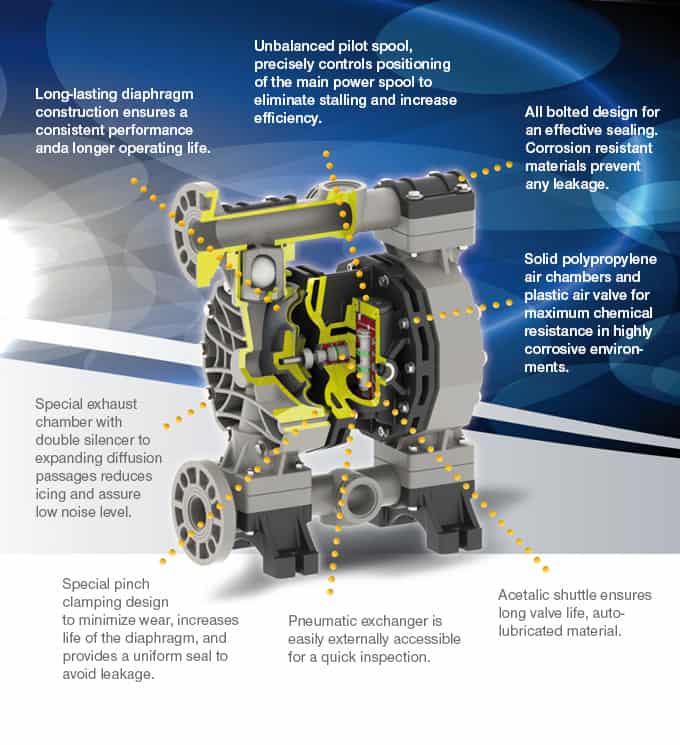

FEATURES AND BENEFITS

- Adjustable flow rate and head via air pressure.

- 100% tested after final assembly regarding deadheading, priming, and sealing.

- ATEX certifications for all versions: conductive plastic pumps are available.

- Efficient air distribution design: low air consumption.

- All plastic air system: robust and corrosion-resistant in harsh environments.

- Special air system: lube-free, non-stall, non-freeze, designed to operate at low noise levels.

- Pumping of aggressive and flammable media, viscous liquids, also with solids or gas.

- Suitabe for use in hazardous areas or areas with high humidity.

- Fully submersible.

- Dry-running without damaging the pump or system.

- Pump restart without any problems.

- Pumping against closed discharge without any pump damage. A diaphragm pump will stop if discharge will be closed (1:1 ratio between air and discharge pressure).

- Dry self-priming up to 6 meters.

- Efficient performance: high flow rates through optimal casings designs.

- Portable and compact for multi-location use, optionally available with trolley.

- Different connection possibilities through different suction and discharge ports.

- Bolted construction prevents any leakage and assures maximum safety

- Easily and quickly to maintain without the need of any special tools

Pump style : FD = Food grade design

Reviews

There are no reviews yet.