Description

Automatic electric hot steam-generator

- with capacity from 20 kW up to 40 kW (from 26 up to 52 kg of hot steam per hour) – if returned condensate is not reused (the condesate recovery set is not included)

- with capacity from 20 kW up to 40 kW (from 30 up to 60 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included)

Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 4.5 or 8.5 bar (it depends on the version ordered).

This steam-generator is available with single or with two independent heaters (two independent heating elements). The steam-generator shell is manufactured in accordance to the current PED regulations.

Made in EU

Recommended use :

- Heating the wort brew machines – recomended for brewhouses with maximal usage volume 300 liters per one brew

- Heating the water, beverages or chemical solutions in the water tanks, CIP stations, boilers, pasteurisers etc.

- Heating the food processing machines

- Sterilization of the vessels, pipes, hoses, stainless steel kegs, filters, food production equipment, farmacy equipment … with hot steam

Parameters and accessories :

| Technical data | Model : MXSG-40 : GHIDINI MAXI-60 20kW |

| Capacity – if the returned hot condensate is not reused | Switcheable : 20 kW or 40 kW (26 or 52 kg of hot steam per hour) |

| Capacity – if the returned hot condensate is reused | Switcheable : 20 kW or 40 kW (30 or 60 kg of hot steam per hour) |

| Pressure and temperature of outgoing steam (4.5 bar version) | From 1 bar to 4.5 bar / From 100°C to 155°C |

| Pressure and temperature of outgoing steam (8.5 bar version) | From 1 bar to 8.5 bar / From 100°C to 177°C |

| Power supply voltage and frequency (EU version) | 3-phases 380-420V / 50 Hz |

| Power supply voltage and frequency (US version) | 3-phases 220-240V / 60 Hz |

| Boiler capacity | 55 liters |

| High temperature pump | 0.55 kW |

| Electric heaters | 2x 20 kW |

| Safety overpressure valve | 5 bar or 9 bar (depending on the version) |

| Water inlet | BSP 1/2″ (ET) |

| Condensate return (only if the condensate recovery set is included) | BSP 1/2″ (ET) |

| Steam outlet (with a ball valve) | BSP 1/2″ (IT) |

| Total dimensions (without the condensate recovery set) | L x W x H : 830 x 830 x 570 mm |

| Net weight (without the condensate recovery set) | 114 kg |

| Gross weight (without the condensate recovery set) | 131 kg |

| Packing dimensions with the palett (without the condensate recovery set) | 900 x 900 x 820 mm |

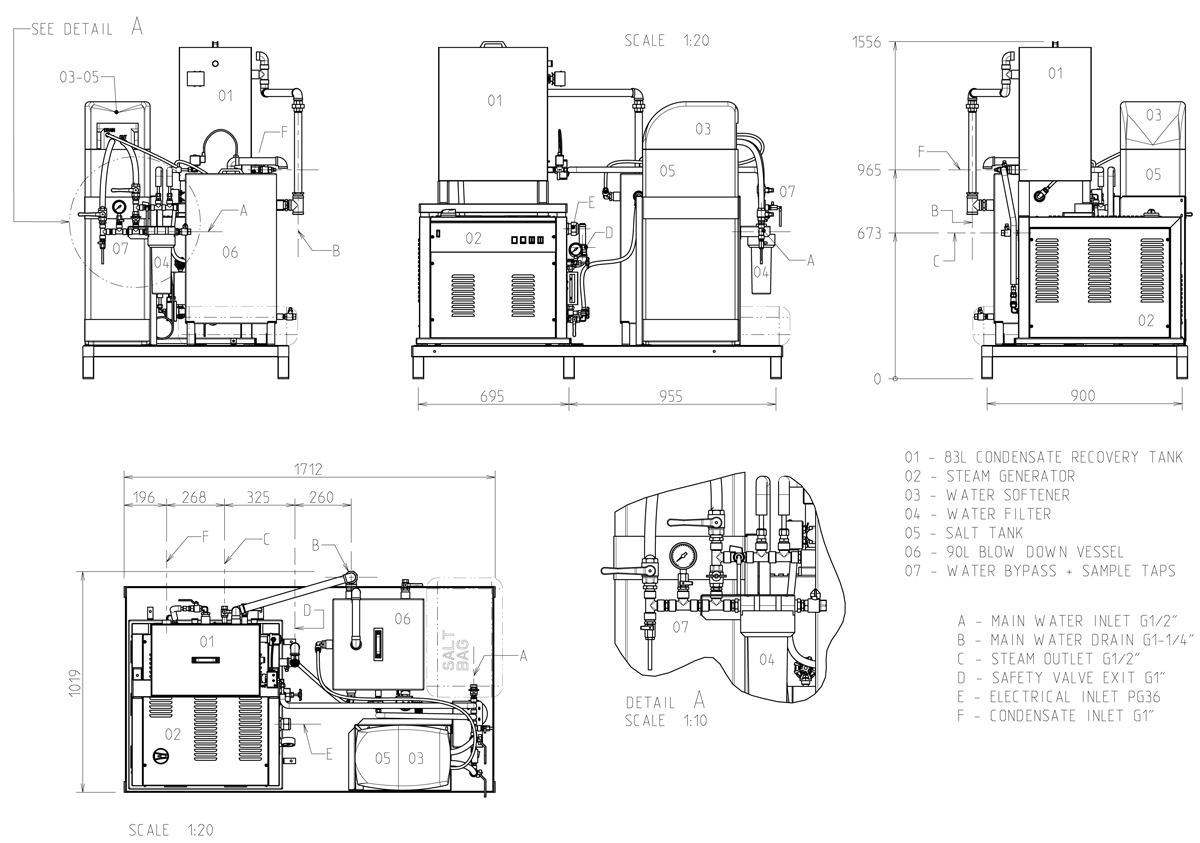

Dimensions and description of the GHIDINI MAXI-60 40kW steam generator with basic recommended accessories with all connections :

Optional equipment :

| CT-MX60 : Stainless steel tank for returned condensate 83L, including level sensor, solenoid valve and thermostat (for MAXI 20/40/60) | On demand |

| CT-MX60S : Stainless steel tank for returned condensate 83L, including level sensor, solenoid valve and thermostat | all components in contact with water are made in stainless steel (for MAXI 20/40/60) | On demand |

| CTMK-MX60 : Kit to mount the condensate recovery tank above the steam generator (for MAXI 20/40/60) | On demand |

| SB304-MX60 : Steam boiler in stainless steel AISI 304 (for MAXI 20/40/60) | On demand |

| SB316-MX60 : Steam boiler in stainless steel AISI 316 (for MAXI 20/40/60) | On demand |

| CSW304-MX60 : All components of the steam generator in contact with water in stainless steel AISI 304 (for MAXI 20/40/60) | On demand |

| CSW316-MX60 : All components of the steam generator in contact with water in stainless steel AISI 316 (for MAXI 20/40/60) | On demand |

| SOJ-MX60 : Outer jacket and electric switchbox in stainless steel AISI 304 (for MAXI 20/40/60) | On demand |

| TSD-MX60 : Cooling tank with the boiler sludge draining system (for MAXI 20/40/60) | On demand |

| ASR-MX60 : Automatic sludge removal (for MAXI 20/40/60) | On demand |

| WTS-MX60 : Water treatment system – necessary to prevent damage to the machine by mineral deposits (for MAXI 20/40/60) | On demand |

| SF-MX60 : Steel frame with adjustable feet under the steam generator (for MAXI 60) | On demand |

| SKID-MX40 : The complete compact solution on the frame : storage tank + condensate tank + water treatment system + stainless steel frame + all pipe connections (for MAXI 40) | MXSG-40CSF |

| SSFS-MX12 :Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 1/2″ steam pipe line | SSFS-MX12 |

Warranty : 12 months (for all parts) – A customer with help of our remote support identifies a bad component and then send it to us. Then a spare part will be sent to the customer.

On-site repair services are not included.

Delivery time : from 3 days to 6 weeks (according current store status)

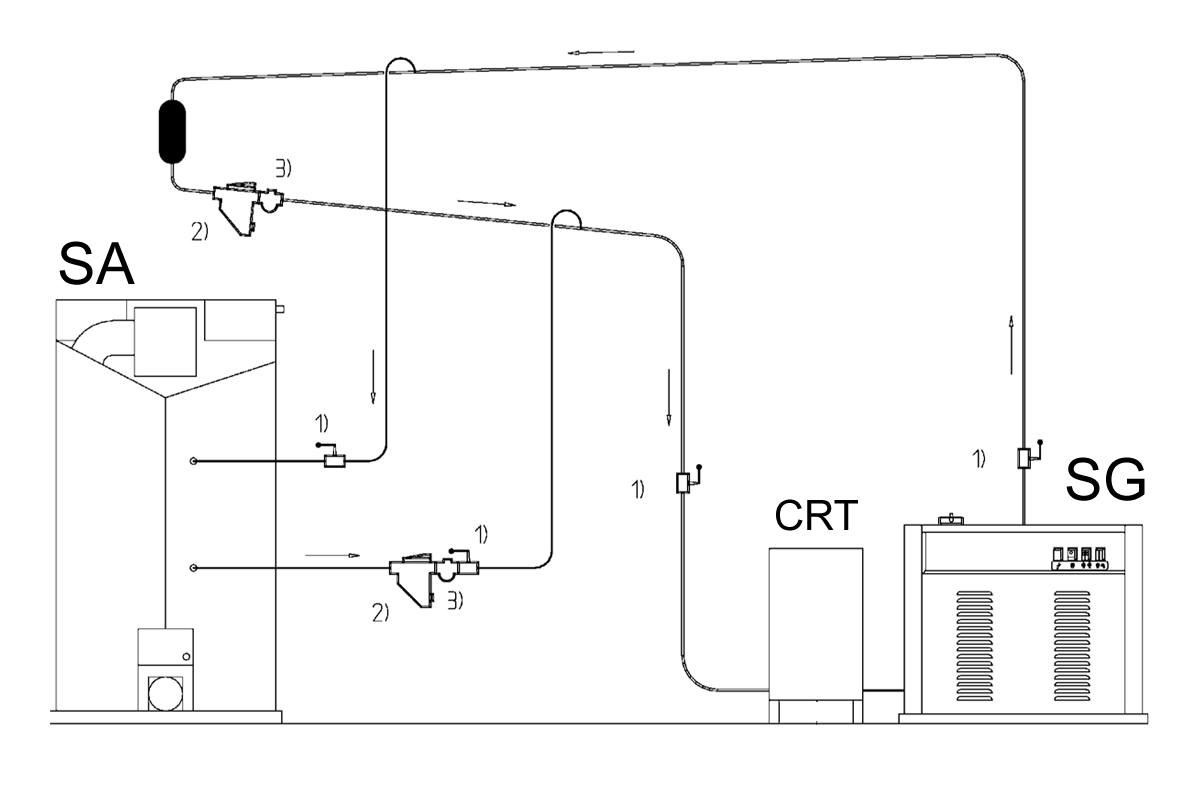

Diagram of a closed-cycle steam circuit (return condensate is reused):

Description :

SG – steam generator

SA – steam appliance

CRT – condensate recovery tank

1 – gate valves

2 – condensate dischargers

3 – check valves

Reviews

There are no reviews yet.