Description

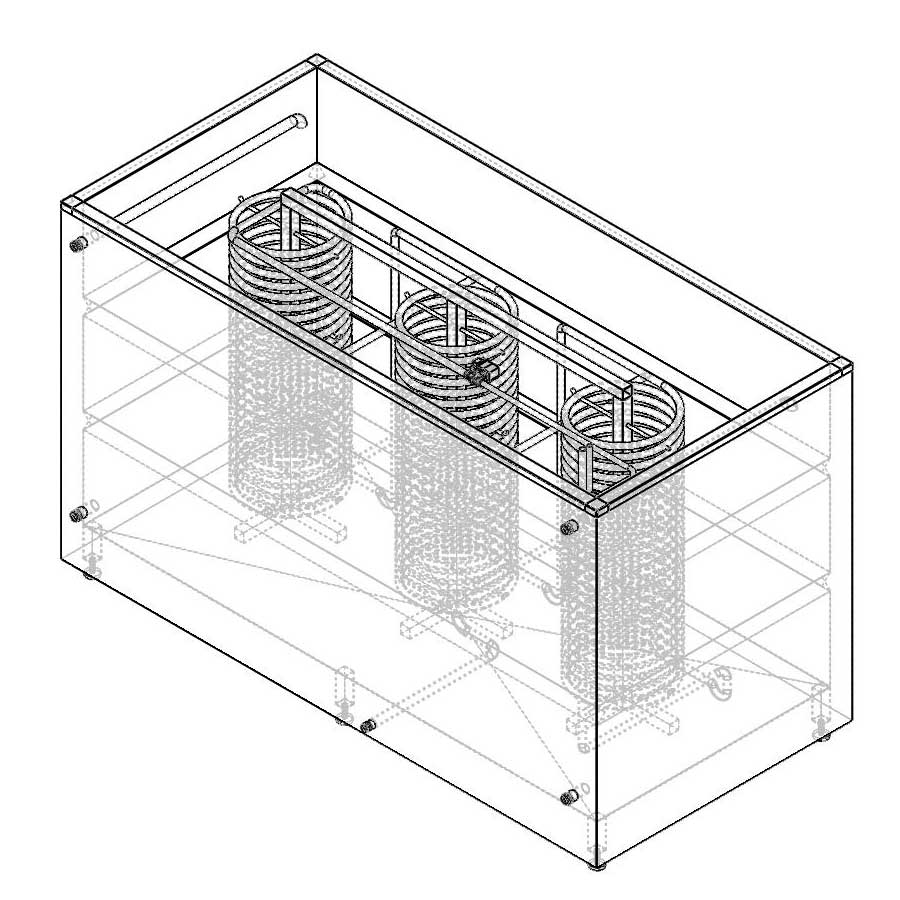

Industrial glycol tank to preparation of cooling ice water 1000 liters with integrated cooling spirals and pumps

The ICWT-1000 Ice Water Tank (the glycol cooling tank with capacity of 1000 liters) with integrated copper heat exchanger (submersible spirals) is designed for an acummulation of cold inside of the mono-propylen-glycol solution and for its subsuqent use in the processes of making, storaging and maturating of beer or other beverages. The tank is fitted with a circulating pump for homogenization of the temperature and for the prevention of the freezing of the copper spirals, with only a minimum of power consuption.

The cooling tank is standardly equipped with a single pump for circulating of the cooling solution inside the closed circuit between the coolled components and the ice water tank.

If the second cooling circuit is used, the Ice Water Tank is standardly equipped with other connection points (but without a pump which is only for surcharge)

The cooling of mono-propylene glycol ensures an external cooling unit GCU, which is always designed for the volume of the ice water tank and required cooling capacity. If required, one ICWT tank may be connected to several external GCU cooling units connected in series to increase the cooling performance. The recommended maximum distance of the external cooling units from the ice water tank is 25 m.

The external cooling units are not included in price of the ICWT Ice Water Tank. It is necessary to order one or more external cooling units separatelly. Pipe connections between the ICWT ice water tank and the extenal cooling units and filling the primary cooling circuit with a coolant have to be ensured by a company certified for installations and maintenance of cooling systems.

The ICWT tank is mounted on six adjustable legs and closed by a stainless steel top cover.

Cooling solution (recommended mono-propylene or glycol solution) is not included. We recommend that you deal with a food-grade liquid according to your application. Recommended concentration of the mono-propylen-glycol in water according to required minimal temperature is defined by its producer and is usually visible on a label of the bottle.

Technical parameters:(parameters can be tailored to the needs of a customer) |

|

| Total volume | 1058 l |

| Useful volume | 1000 l |

| Height | 850 mm |

| Length | 1250 mm |

| Width | 1250 mm |

| Material | 1.4301 (AISI 304) |

| Polyuretan insulation | 50 mm |

| Insulation surface – brushed sheet | 1.4301 (AISI 304) |

| Water inlet 2x | DN 25 |

| Water outlet | DN 32 |

| Thermosensor pocket | ø10 mm |

| Min. Working temperature | -15°C |

| Max. working temperature | 85°C |

| Drain and filling armature | DN 25 |

Standard electric equipment :

| Thermosensor | NTC |

| Circulating pump | Willo |

| Digital thermometer | DIXEL XR 20 D (1ph 230V 50Hz) |

| Electric switchboard: | |

| Main switch | 3ph 400V 50Hz 16A |

| Compressor contactor | 1ph 230V 50Hz 10A |

| 2x motor starter | 4-6A 3ph 400V 50Hz |

| Standard plastic electric switch box with a simple control system | in price |

| Stainless steel electric switch box with a simple control system | + € 250,- |

The listed equipment is valid for the standard version with one external cooling unit connected on the primary circuit and one secondary cooling circuit (for example for cooling the fermenters). Price of the electric equipment needed for a cooling system with more cooling units, with more secondary cooling circuits or with non-standard control system will be calculated individually according to customer´s requirements.

Warranty:

- Tank 1000 l 36 months

- Pump 24 months

- Electric components 12 months

Reviews

There are no reviews yet.