Description

HTJC-1000MG is a double walled mixing tank designed as a fruit jam cooker in which the heating media is glycerol for food. Can be used also for mixing and homogenizing other food material with low density in liquids.

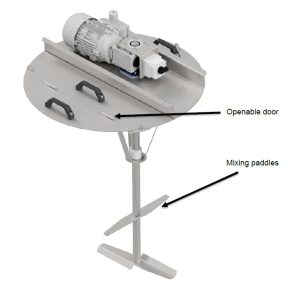

The machine has a build-in mixing unit, which ensures that the food materials do not stick. Bottom mixing motor with food grade silicone scrapers to prevent burning of the food material on the heated walls of the tank. The machine automatically controls the heating temperature. Heavy duty rubber machine feet. Automatic control system. It requires minimal maintenance.

HTJC-1000MG has usable volume 1000 liters and is made of stainless food steel of AISI 304 or AISI 316L (according to the selected version).

Technical details of the mixing-homogenizing tank (fruit jam cooker) 1000 liters

- Usable volume : 1000L / Capacity of 1200 kg

- Agitator : Motor 1.50 kW / 1:100 gearbox / Rotation speed : 14.5 rpm (up to 22 rpm if the frequency inverter is installed)

- Heating : 4x 12 kW / total 48 kW

- Electric demands: 50 kW, 3ph 400V / 50Hz , 63 A

- Maximal temperature : 140°C

- Material: Stainless steel AISI 304 or AISI 316L (according to the selected version)

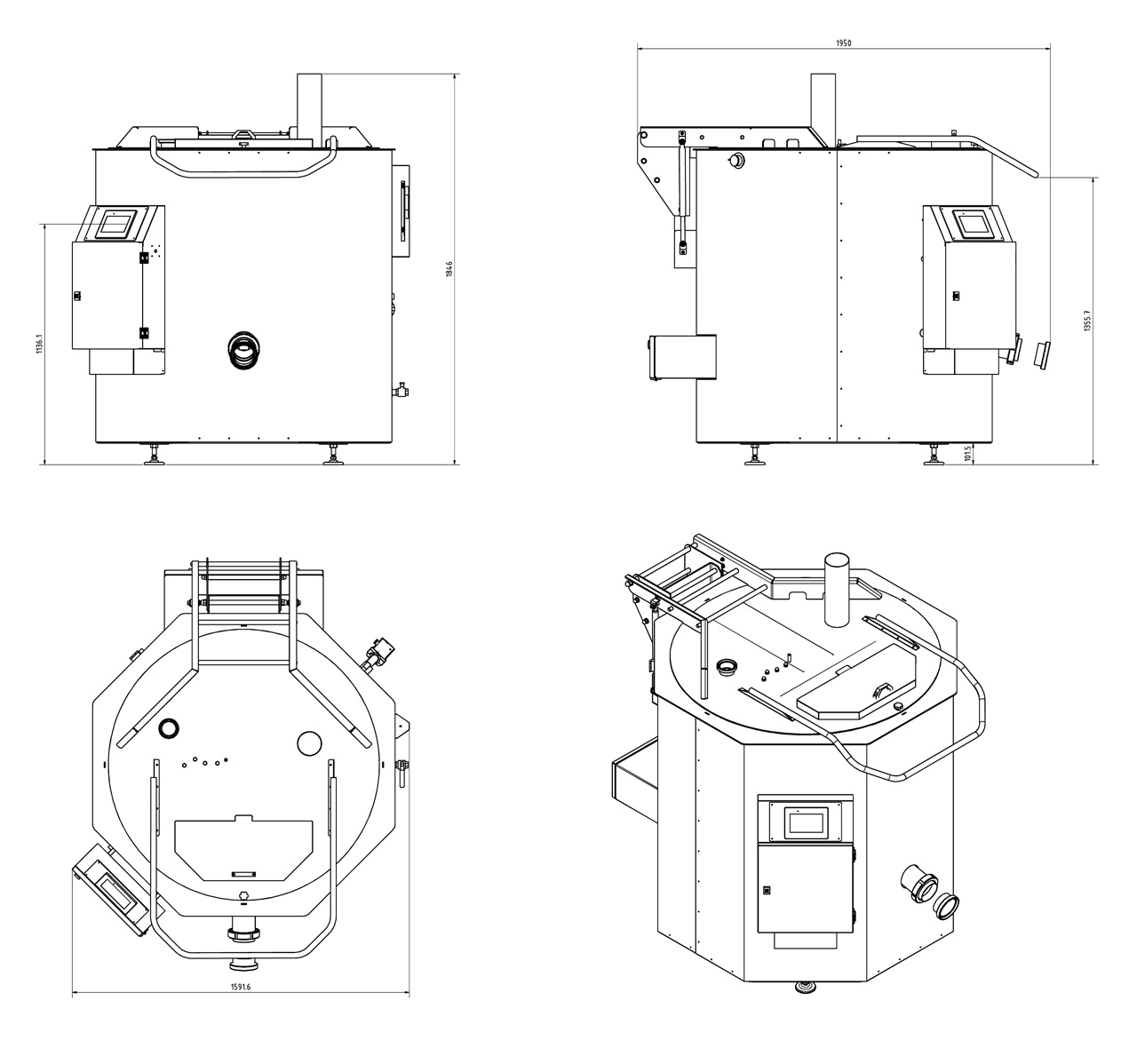

- Dimensions: 1950 x 1600 x 1850 mm

- Weight: 1050 kg

- Double walled mixing tank / jam cooker in which the industrial glycerol for food is used as a heat transfer media

- IP65 certified electronics

- Automatic temperature control (PLC HMI Schneider with a touch LCD)

- Easy to clean

- Requires minimal maintenance

- Input pipe / hose connection: DN 65

- Output pipe / hose connection: DN 100

- Filling level indicator

- Power supply cable 2m (with the plug 3ph 400V 63A 5-pin)

- Mixer with silicone scrapers against burning

- Thermometers : 2pcs (one in the heating jacket, one in a product)

- IP65 certified electronic

Main advantages and features :

The HTJC-1000MG offers (in comparation with the smaller HTJC types) several significant advantages :

- Insulated structure – allows the glycerin to maintain a temperature of 50°C for days, resulting in substantial energy savings

- Individually switchable heating elements

- Frequency inverter included as standard

- PLC control system

- Recipe storage for customized processes

- Core temperature sensor

- Heating jacket temperature sensor

- Integrated timer

- Programmable operation, e.g.: → heat to 60°C for 45 minutes, then cook at 99°C for 70 minutes

- Thanks to the software-based control system, we can program almost any custom process the customer may require.

- Moreover, with remote access capabilities, manufacturer-level support can be provided if needed.

Delivery period :

- Versions made of material AISI 304 … 8-10 weeks

- Versions made of material AISI 316 … 10-12 weeks

Glycerine as the heating medium

The heating medium with which the machine is filled consists of 80% pure glycerine and 20% water.

The heating jacket can be easily refilled with glycerine. There is a sealed connection point on the side wall through which anyone can top it up if necessary.

The machine is delivered in a filled condition (approximately for 85% of total cooling jacket capacity).

It cannot be filled completely (100%) because we must take into account the expansion range of water and glycerine.

No replacement of the glycerine after each use is required until it is not evapored more than 20% of entire volume – its lifetime is usualy approximaly 1000 working hours.

Dimensions :

Optional inner copper surface :

Optional equipment :

| Code | Description | Price |

| HTJC-1000MG-ICS | Inner copper surface | € 8490,- |

| HTJC-1000MG-FRI | Frequency inverter | € 1990,- |

Reviews

There are no reviews yet.