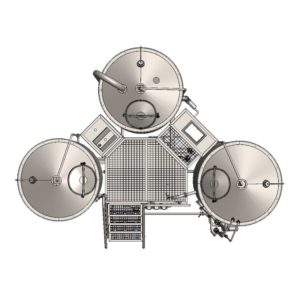

Description

Automatic electric hot steam-generator (set of the 2x ESG-150) / steam pressure from 2 to 6 bar

– with capacity from 25 kW up to 200 kW (from 37 up to 300 kg of hot steam per hour) – if returned condensate is reused

– with capacity from 25 kW up to 200 kW (from 32 up to 260 kg of hot steam per hour) – if condensate is not reused

Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 6 bar.

This steam-generator set is available with eight independent heaters (eight independent heating elements). The steam-generator shell is manufactured in accordance to the current PED regulations.

Made in EU

Recommended usage :

- Heating the wort brew machines – recomended for brewhouses with maximal usage volume 4000 liters per one brew

- Heating the water, beverages or chemical solutions in the water tanks, CIP stations, boilers, pasteurisers etc.

- Heating the food processing machines

- Sterilization of the vessels, pipes, hoses, stainless steel kegs, filters, food production equipment, farmacy equipment … with hot steam

Parameters and accessories :

- Power from 25 kW to 200 kW

- Steam production capacity from 37 to 300 kg of hot steam per hour – if returned condensate is reused

- Steam production capacity from 32 to 260 kg of hot steam per hour – if returned condensate is not reused

- Working pressure and temperature of steam max. 6 bar / 155°C

- Water treatment unit with automatic regeneration – capacity of ionex 80 liters

- Particulate filter

- Stainless steel condensate tank

- Four sets of heaters.

- High temperature pump – 3pcs

- Sound intensity level < 70 dB(A)

- Boiler body made of steel (optionaly stainless steel AISI 304)

- Boiler capacity 4×57 liters

- Boiler heater 25 – 200 kW

- Safety overpressure valve 7 bar

- Adjustable relief valve fot outgoing steam

- Built-in electric switchboard cabinet

- Built-in centrifugal pump

- Power supply 3x400V – 3ph – 50 Hz

- Working temperature + 5 ÷ + 80 °C

- Net dimensions 1700 x 800 x 1200 mm.

- Net weight 290 Kg

- Overall dimensions (packaging included) 800 x 1000 x 1200 mm

- Gross weight (packaging included) 320 Kg

Standard equipment :

| Four independent heaters 8 x 25 kW | in price |

| Equipment for maximal pressure 6 bar / 165°C | in price |

| Simple water treatment system – capacity 80 :

– system of deferred regeneration |

in price |

| 2x Pressure tank 57 liters | in price |

| 2x Adjustable pressure valve for outgoing steam | in price |

| 1x Built-in electric switchbox | in price |

| 2x Centrifugal pump | in price |

| 2x Safety pressure valve 7 bar | in price |

| 1x Stainless steel tank for condensate (only version with the condensate return) | in price |

Optional equipment :

| Simple stainless steel frame on adjustable feet (only under the steam generator unit – without pipe connections, wire connections and water treatment) | € 1500,- |

| Compact solution – all system is installed on the stainless steel frame (including all pipe connections, wire connections, water treatment) | On demand |

| Set of recommended spare parts : … includes : 2 pcs heating element 20 kW + seal, 2 pcs main contactor, 12 pcs fuse 50A, 2 pcs level indicator (glass pipe), 1pc PQM pump, 1pc pressure switch, 1pc solenoid of pump, 2 pcs boiler floater + seal, 1pc floater for the condensate tank , 2 pcs valve for level indicator , 1pc thermostat or the condensate tank , 2 pcs manometer 0-10 bar, 2 pcs non-return valve | € 3690,- |

Warranty : 12 months (for all parts) – A customer with help of our remote support identifies a bad component and then send it to us. Then a spare part will be sent to the customer.

On-site repair services are not included.

Delivery time : from 3 days to 6 weeks (according store status)

Reviews

There are no reviews yet.