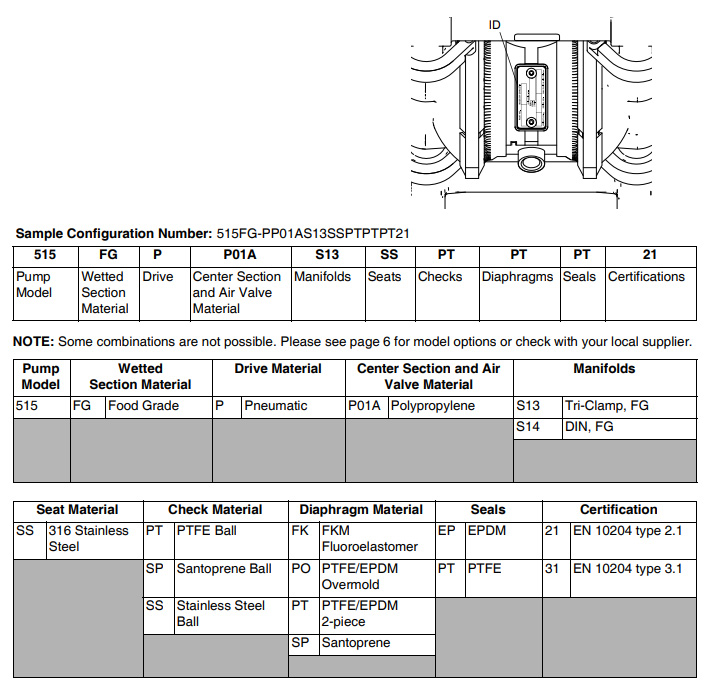

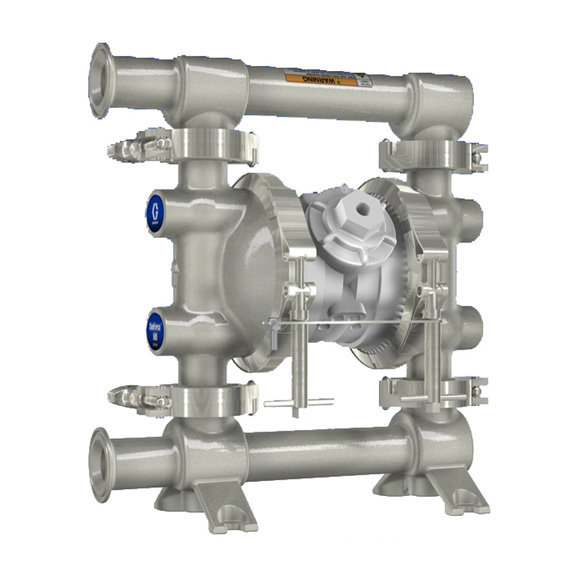

Description

The Graco Saniforce 515 AODD FD5113 pneumatic stainless steel diaphragm pump with the FDA certification for feeding beer or other beverages. This device works without electrical consumption – it needs only pressure air and a pressure reduction valve. Minimalized mechanical impact on beer. Pump volume power : 28 – 56.7 liters / min. (1.7 – 3.4 m3/hour)

This pump includes a certificates for use with food processing – CE, ATEX, IECEx, 1935/2004/EC and FDA

Main features :

- 20 to 30 percent better flow rates than other products available on the market.

- Patented unstallable unbalanced air valve design which avoids stalling issues associated with other pumps.

- Exhaust valves that divert cold exhaust air from ice-prone components, which prevents freezing and downtime.

- Ability to pass even large shear-sensitive solids without degradation or heat build-up.

- The ability to run dry (eliminating the risk of pump damage).

- Gentle pumping action will not froth or separate fluid, improving end-product quality.

Certifications :

Food Grade Certification :

All fluid contact materials are FDA-compliant and meet the United States Code of Federal Regulations (CFR) Title 21 for repeated use in food-processing machinery. The pump user must verify that the construction materials meet their specific application requirements.

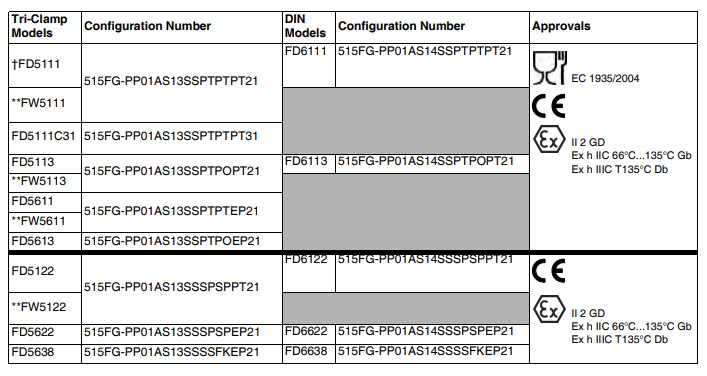

Food Grade certificates depend on the materials of the selected version :

ATEX certification :

† USP Class VI classified

** Pump tested with water

ATEX T-code rating is dependent on the temperature of the fluid being pumped. Fluid temperature is limited by the materials of the pump interior wetted parts. See Technical Data for the maximum fluid operating temperature for your specific pump model.

General Description:

- Fluid Connection: Sanitary Flange (TriClamp DIN 32676)

- Material of all wetted solid parts: AISI 316L Stainless Steel

- Material of all wetted flexi parts : EPDM, PTFE, Santoprene®

- Material of all non-wetted external parts : AISI 300 Stainless Steel

- Ball Material: PTFE

- Diaphragm Material: Santoprene®

Parameters :

| Pump type | Metallic air operated double phase diaphragm pump |

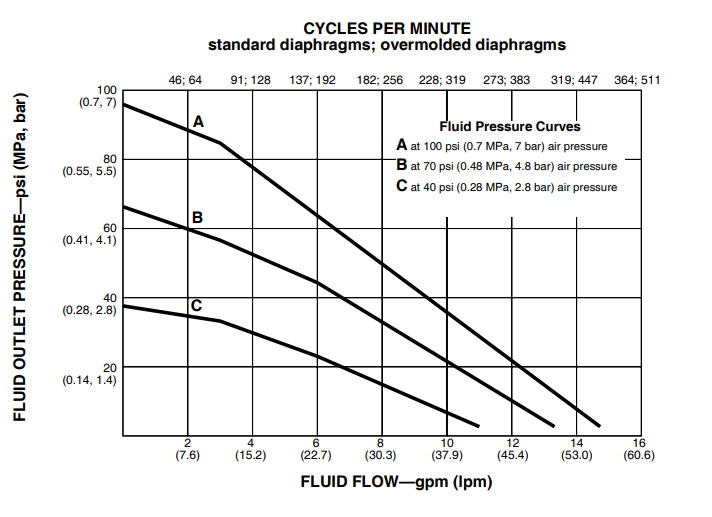

| Maximum flow rate | 56.7 liters / minute (3.4 m3 / hour) |

| Weight | 10 kg (23 lb.) |

| Material of all wetted solid parts : | Stainless steel AISI 316L |

| Material of all non-wetted external parts : | Stainless steel AISI 300 |

| Material of all wetted flexi parts : | EPDM, PTFE, Santoprene® (CAUTION: Santoprene® may be used only with non-fatty, non-oily foods or alcohols up to 15%.) |

| Material of pump diaphragms: | Santoprene® |

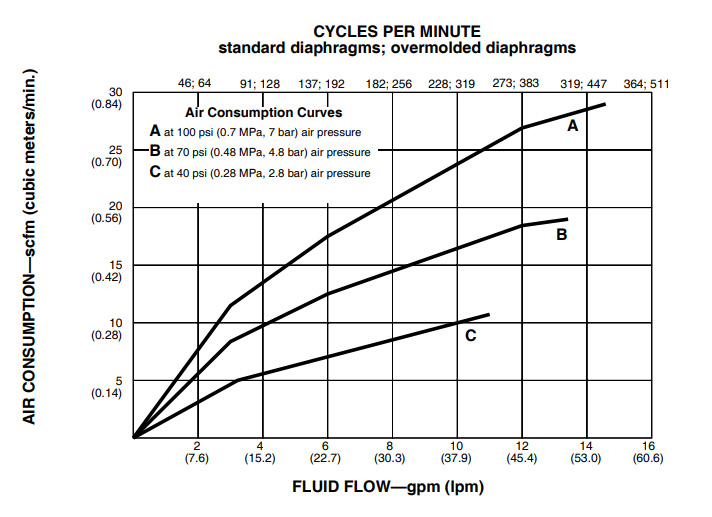

| Maximum air consumption (at 7.0 bar pressure) | 0.8 m3/min (28 scfm) |

| Air consumption at 70 psi (at 4.9 bar pressure) | 0.5 m3/min (18 scfm) |

| Air inlet pressure operating range | 20-100 psi ( 1.4 – 7.0 bar) |

| Maximum product inlet pressure | 10 psig (0.69 bar) |

| Maximum outlet pressure | 100 psig (7.0 bar) |

| Maximum suction lift (Dry) | 15 ft. (4.6 meters) |

| Maximum suction lift (Wet) | 25 ft. (7.6 meters) |

| Maximum particle size | 1/8” diameter (3.2 mm) |

| Maximum temperature limits (diaphragm / ball / seal material) | -40° to 180°F (40° to 82.2°C) valid for the Santoprene® flexi parts |

| Maximum temperature limits (diaphragm / ball / seal material) | -40° to 220°F (40° to 104°C) valid for the PTFE flexi parts |

| Maximum temperature limits (diaphragm / ball / seal material) | -40° to 250°F (40° to 121°C) valid for the EPDM flexi parts |

| Maximum temperature limits (solid parts) | -40° to 250°F (40° to 121°C) valid for the stainless steel solid parts |

| Environmental temperature range | 40°–120°F (4°–49°C) |

| Minimum fluid temperature | 40°F (4°C) |

| Noise Level @ 70 psig, 60 cpm | 78 dB(A) at 70 psi (0.48 MPa, 4.8 bar) |

| Maximum viscosity of a product | 10000 cps |

| Maximum recommended cycle rate for continuous duty | 182 cycles per minute |

| Pressure air inlet | NPT 1/4″ internal thread (female) |

| Air exhaust port | NPT 3/8″ internal thread (female) |

| Product inlet | DIN 32676 TriClamp 1″ (DN 25) – Connection disc with diameter of 50.5 mm |

| Product outlet | DIN 32676 TriClamp 1″ (DN 25) – Connection disc with diameter of 50.5 mm |

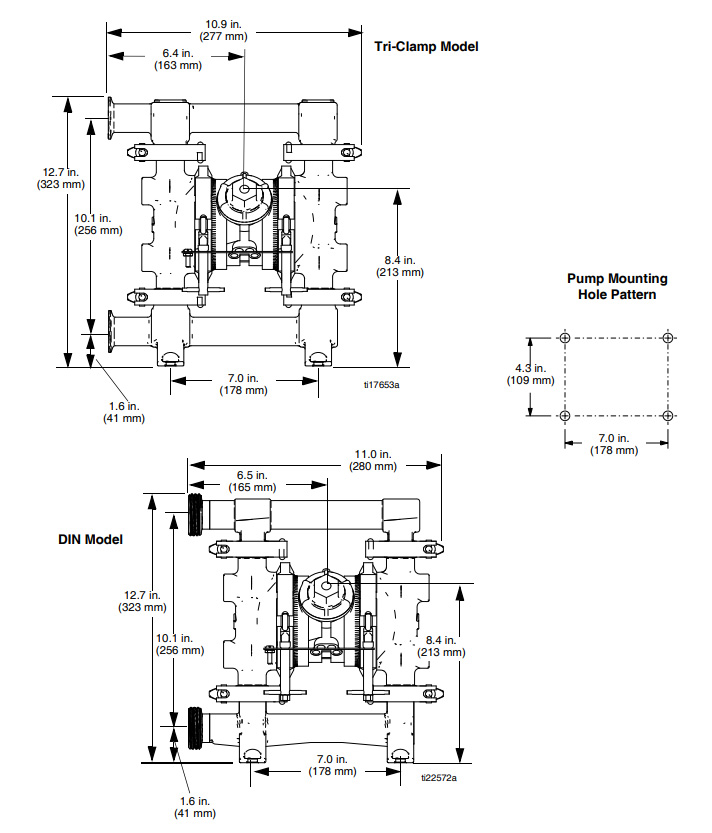

Dimensions :

Performance curves :

Air consumption chart :

Reviews

There are no reviews yet.