Description

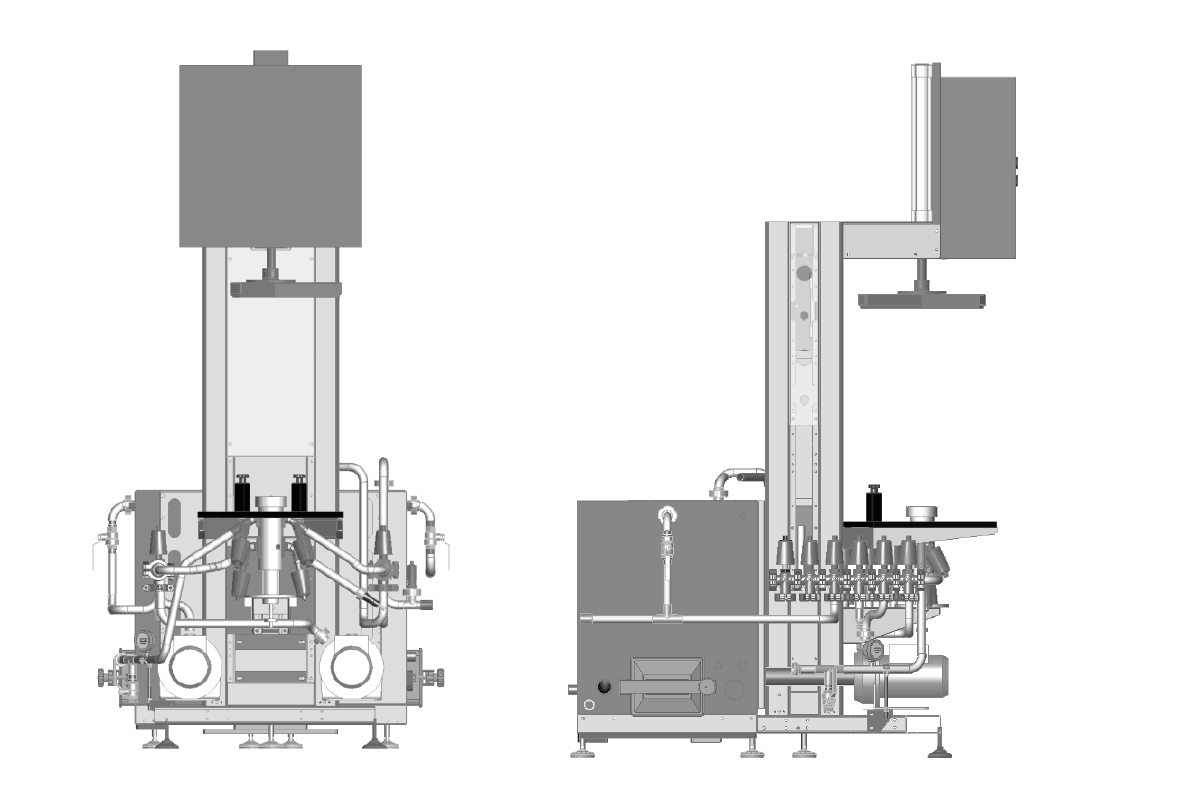

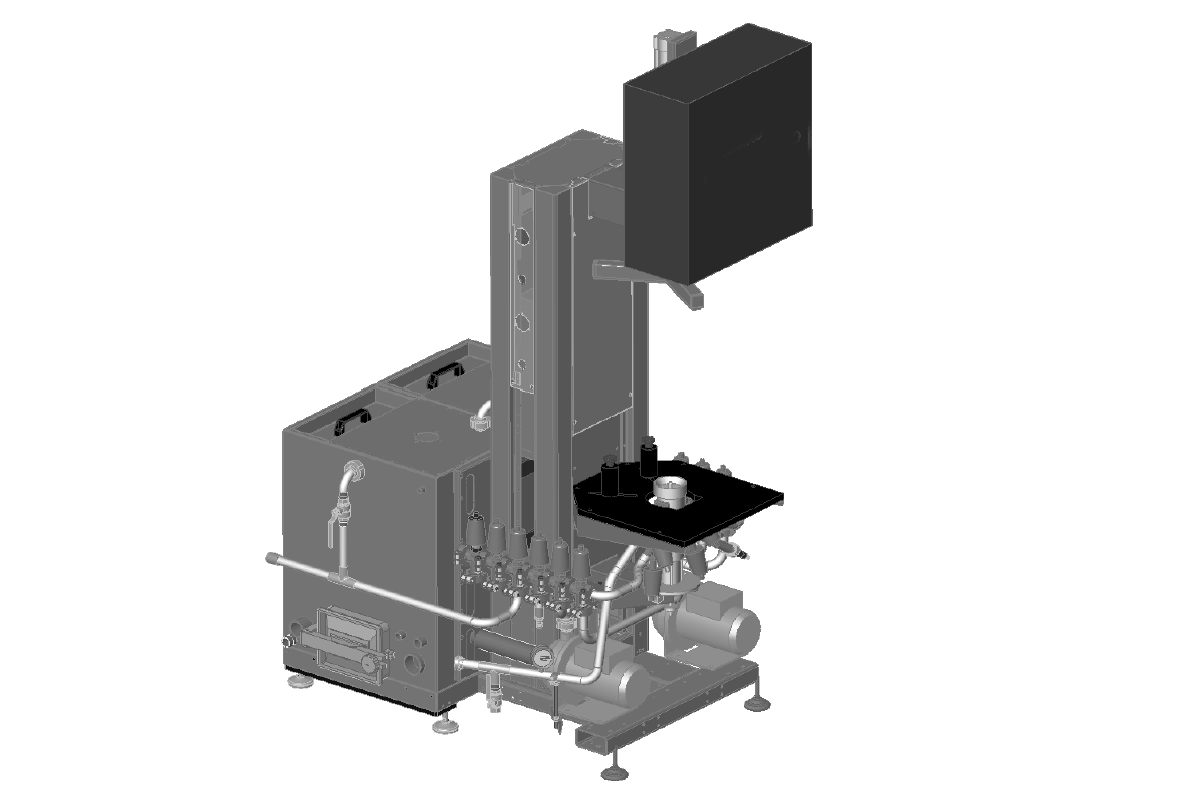

For the filling and washing of stainless steel kegs, with operation capacity of 16-19 kegs/hour, we recommend the KWF-19 machine. This is a semiautomatic machine designed and made with special care paid to hygiene.

Cleaning and filling cycles – capacity:

- 20L or 30 L kegs : 19pcs per hour

- 50L kegs : 16pcs per hour

The entire structure of the machine and the parts that are contact with the liquid and beverage are entirely made out of AISI 304 stainless steel. The filling head was conceived with careful detail to exclude any type of contact with air on the part of the product being worked and to ensure a filling process that’s completely sterile.

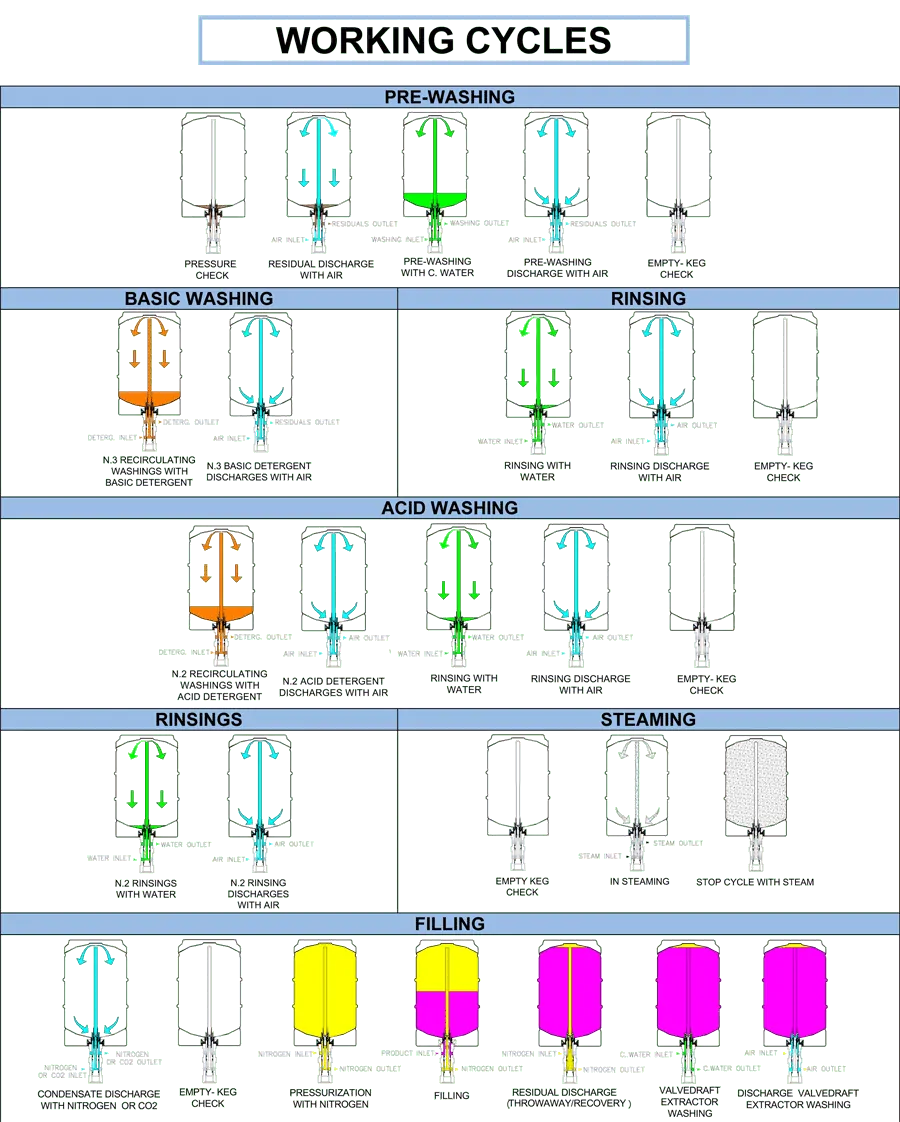

The keg cleaning and sanitizing system was conceived to ensure:

a) perfect cleaning of the kegs

b) checking and monitoring of the rinsing phase

c) at the end of every work phase, the checking for the absence of liquid in the kegs thus confirming the impossibility of unwanted rackings, to then be able to provide the assurance that the discharge phase has occurred.

The system is fitted for connection with a steam generator for hot sterilization of the containers.

The command and control parts are positioned in a watertight control board and electronically managed thanks to the use of a PLC.

Our valves for the controlling of the washing and filling cycles are made out of turned-ingot stainless steel and, thanks to their perfect internal finishing, allow for easy washing and sterilization, thereby preventing filth and grime from settling.

In addition, the special solid steel structure guarantees excellent resistance to wear and minimizes the need for ordinary maintenance operations.

PRICE INCLUDES

- Stainless steel frame

- AISI 304/316 L stainless steel product piping

- AISI 304 L stainless steel control board

- 5m feeder cable

- Adjustable supporting feet

- Keg-type regulator

- Washing and filling function via PLC

- Touch screen

- Liquid-detection sensor at each rinsing, washing and steaming phase (no condensation)

- Filling with pressure sensor and maximum liquid-level detection

- Detergent heating via steam pocket or electrical resistance

- Electrical outlet for connection to the feed pump

- CIP (Clean-in-place) tank for alkaline sanitizing detergent

- CIP (Clean-in-place) tank for acidic sanitizing detergent

- Pump for the re-circulation of the basic and acidic detergents

- Kit for the washing and sanitation of the filling heads

- Use and maintenance manual in Italian and English

TECHNICAL PARAMETERS

BASIC PARAMETERS

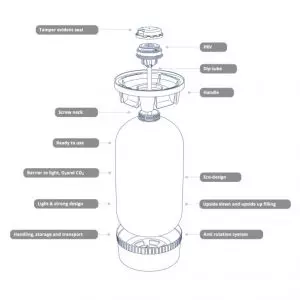

Filling range: stainless steel kegs with capacity of 10-50 liters

Product: Beer

Filling/washing heads: 1pc

Accurancy of the liter counter: ± 0.20%

Average accuracy of filling: ± 1.5%

Accident-prevention: Dual buttons for cycle starting

Resistance to disinfection: water – chemicals – steam

PRODUCTION CAPACITY

Max. hourly keg cleaning/filling : 20/30L : 19 pcs/hour

Max. hourly keg cleaning/filling : 50L : 16 pcs/hour

MATERIAL

Construction Material: AISI 304 L stainless steel

Material which is in contact with the liquid: AISI 304/316 L stainless steel & EPDM/PTFE/Silicone

DIMENSIONS AND WEIGHT

Height of work table : 850 – 870 mm

Dimensions WxDxH : 1200x1600x 2350 mm

Weight : 430 Kg

ELECTRICITY

Filler’s installed power : 1.5 kW

Power of the resistances (if present) : 4.5 kW

Number of phases : 3/PE

Voltage (AC) : 400 V

Frequency : 50 Hz

CONSUMPTION

Max. liquid flow rate : 3600 l/h

Product Pressure : 2.0 – 2.5 bar

Air pressure : 6-7 bar

Air flow rate : 850 l/min

Air consumption : 245 l/min

CO2 pressure : 6 bar

CO2 flow rate : 700 liters/min

CO2 consumption : 40 liters/min

Water pressure : 3 bar

Water flow rate : 3600 liters/hour

Water consumption : 400 liters/hour

Maximal steam pressure for heating, if provided : 2 bar

Steam pressure for sterilization of kegs : 2.5 bar

Heating steam consumption : 24 kg/hour

Sterilization steam consumption : 12 kg/hour

CONNECTIONS

Product : DN 25 / DIN11851 (Dairy Coupling) or DIN 32676 (TriClamp)

Compressed air : BSP ⅜” outer thread (slide valve)

Nitrogen : BSP ⅜” outer thread (gas)

Detergent-heating steam :BSP ½” outer thread ( gas)

Sterilization steam : BSP ½” outer thread (gas)

Water : BSP ¾” outer thread (gas)

Electric supply : 3-phase +N 400V / 50 Hz / 16A

WORK CYCLES

RECOMMENDED CHEMICAL DETERGENTS

| Code | Chemical detergent |

| 10006-25K | Bio net Kegs 25 kg. jug |

| 10022-25K | Filterklin Ph 25 kg. jug |

OPTIONAL ACCESSORIES

| Code | Description | Price € |

| 13169 | Router for remote diagnostics and software service | on demand |

| 126k037 | Magnetic liter counter | on demand |

| 126k154 | Coalescence filter with stainless housing with 5 “cartridge (air/N/CO2) |

on demand |

| 126k155 | Gas filter with stainless housing with 0.2um cartridge (air/N/CO2) | on demand |

| 126k150 | Steam filter with 1×10 “Housing with AISI 316 stainless steel cartridge | on demand |

| 126k020 | Modification for non-standard client kegs | on demand |

| 126k021 | Keg-probe rinsing | on demand |

| 126k147 | Long 2 m stainless steel roller conveyor on input/output | on demand |

| 126k136 | Short 0.5 m stainless steel coated idler roller conveyor on input/output | on demand |

| 126k096 | End of the keg line – the manual keg facilitator | on demand |

| 126k040 | Kit for pasteurizer recirculation washing | on demand |

| 126k081 | Kit hot water valve | on demand |

| 126k156 | Alimentary mobile centrifugal feed pump 2.5 bar with the by pass on the cart | on demand |

| 126k602 | Kit of main recommended spare parts | on demand |