Description

The KWF-35 is an equipment for semi-automatic washing, sanitation and filling of kegs for beer, cider, wine (and other beverages).

Operating capacity: kegs : 25 – 35 per hour ( washing + filling cycles).

The machine was designed for cleaning and filling kegs with a volume of 15-50 liters. The working performance per hour: 25 to 35 (volume of 50 liters)

The device is controlled by a PLC where it is possible to change the time of every cycle.

Material of washer: stainless steel. Inserting and removing of kegs – manual.

The rinsing and filling stations are located on the base frame. Kegs can be moved manually. Pneumatic cylinder. Programs of washing and filling are performed completely automatically. The process is controlled by PLC with a text display.

- The device was designed for washing and filling of kegs of volume of: 20 – 58 liters

- The washer: stainless steel , control panel: plastic (optional stainless steel). The device is controlled by a PLC .

- Handling with kegs: manually (optionally automatic)

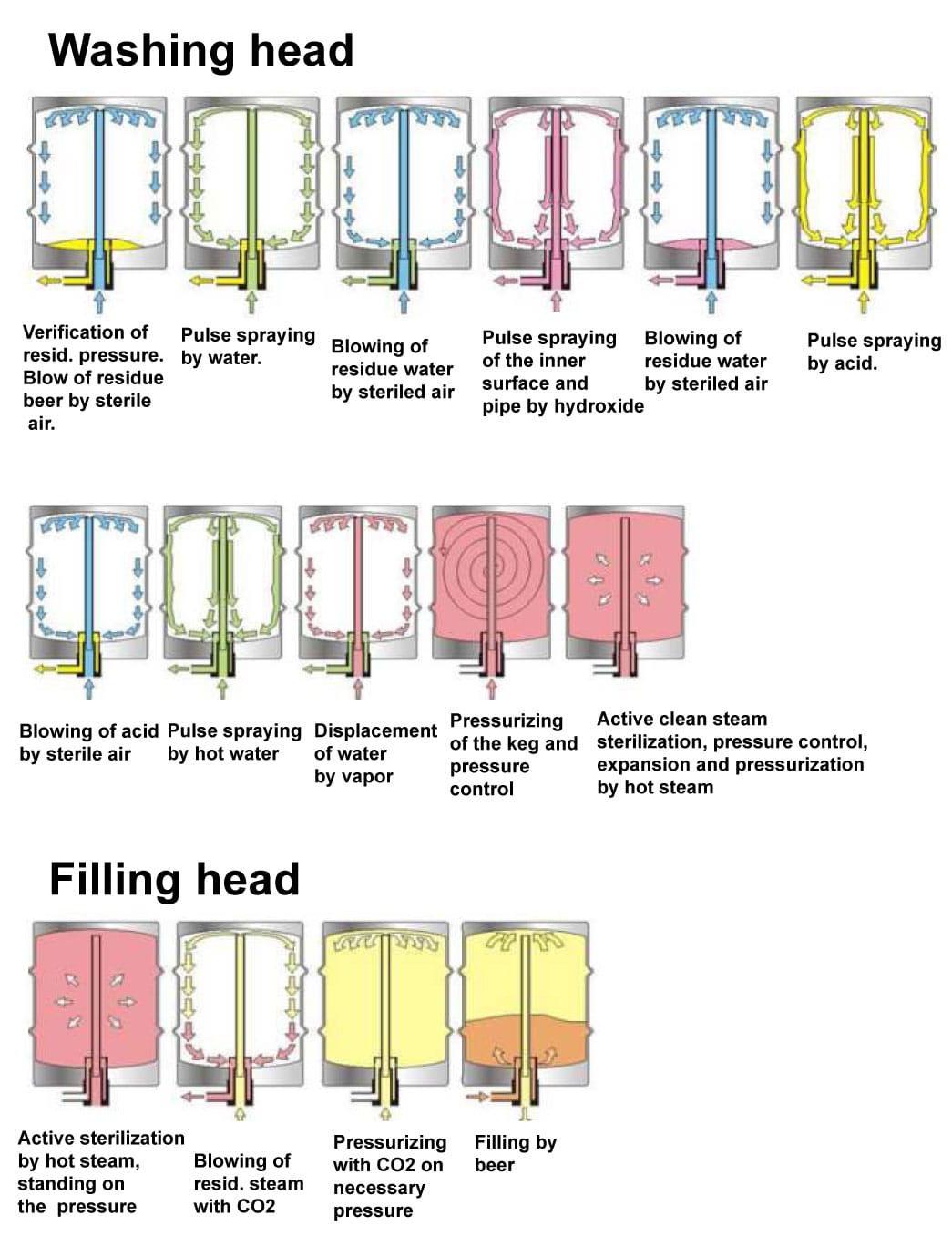

- First head is for washing, the second head is for filling + one head for sterilization of kegs

- Integrated CIP – if there is an external CIP in the brewery – does not need to be included (it is not recommended due to increased consumption of disinfectant solutions) .

- Automatic control of pressure of a keg

The device operates in the following cycles:

Description

– The compact machine is already connected in the factory – with cables and pipes. And everything is tuned and tested.

– Washing: pulsing spray / corrosive / acidic.

– Each step of the washing and filling process is controlled by two-way sensors. Implementation is done carefully.

– The construction is open – accessible from all sides for easy handling.

Basic equipment

– The machine is completely made of stainless steel.

– The standard equipment includes an integrated chrome-nickel cleaner (IP 54), automatic water level control and automatic temperature control.

– Possibility of integration of Siemens or AllenBradley

| Parameters | KWF-35 |

|---|---|

| Perform. mode : washing, sanit., filling | 35 |

| Volume of kegs maximum [ liters ] | 58 |

| Inserting and removing kegs | manually |

| Electrical connection | 3x400V /50Hz 32A |

| Heating | 2 kW |

| Pump | 1000 W |

| Control panel | 400V / 50Hz |

| Switching btw mod washing - filling | auto |

| Sterilisation mode (optionally) | external steam |

| Width / mm / | 1475 |

| Depth / mm / | 1092 |

| Height / mm / | 2160 |

| Weight /kg/ | 240 |

| Average delivery time / months / | 3 |