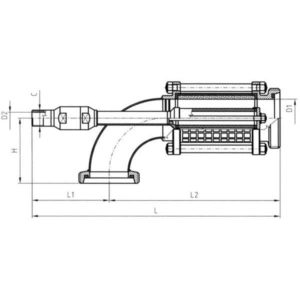

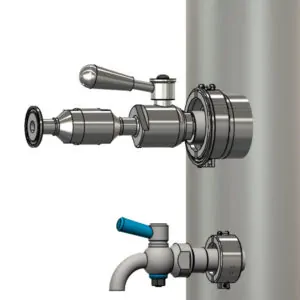

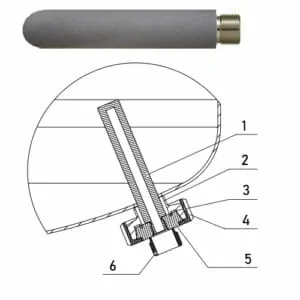

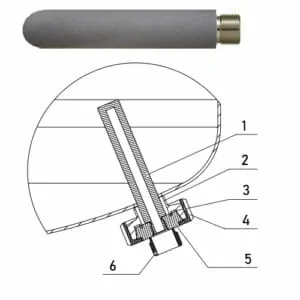

Equipment for the aeration, oxygenation and carbonization of beverages. Oxygenation of wort before start of fermentation. Carbonization of finished alcoholic beverages in the tanks, in carbonization units or in pipe routes before their filling into kegs, bottles or cans.