Description

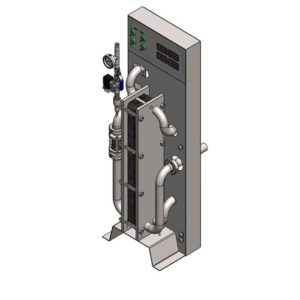

The cooling condenser unit intended for the cooling of the water (usually with glycol solution) in the industrial cooling water tank (ICWT – industrial cooling water tank is not included in this set and it must be purchased individually according to requirements of the customer). The iced water is then used to cooling of the beverage production tanks like fermenters or beer storage tanks and also to cooling other devices in the brewery. This equipment uses a special technical coolant intended to chilling systems that has to be filled and pressurized into the primary circuit only by qualified person. This equipment uses ice water or glycol as coolant. The cooling unit is compatible with all types of ICWT cooling water tanks of our production. The output copper pipes of the condenser cooling unit has to be joined with input copper pipes of the pipe heat exchanger or the primary side of the plate heat exchanger of the ICWT cooling water tank. Cooling capacity 2300 W – 4500 W.

| Temperature | -10°C | 0°C | +10°C |

| Cooling capacity | 2.3 kW | 3.3 kW | 4.5 kW |

Technical parametres:

Technical parametres:

- Exterior dimensions – condenser (WxHxD) 1200x1200x960 mm

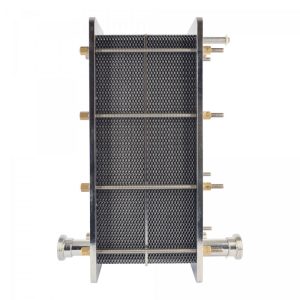

- Exterior dimensions – heat exchanger (WxHxD) 89x461x75 mm

- Weight – condenser : 67 kg

- Weight – heat exchanger : 5.4 kg

- Recommended coolant in the primary circuit : Refrigerant R404A – 3.5 liters

- Recommended coolant in the secondary circuit : Aqueous solution of 40% monopropylene glycol

- Recommended temperature of the glycol solution in the secondary circuit : -4°C

- Nominal voltage 3/N/PE AC 400/230V 50 Hz

- Direct voltage 2/PE DC 24V

- Installed electric power 2.3 kW/50 Hz

- Nominal current of circuit breaker 24 A/C

- Noise 70 dB (at a distance of 1 m from the unit)

Operation parametres (condensation temperature +50 °C):

- Cooling capacity 30/0°C – 3300 W 610 %

- Cooling capacity 10K – 470 liters per hour

- Min. output water temperature -5 °C

- Max. input water temperature +10 °C

- Min. water passage 30 l/min

- Max. input water pressure 1,0 Mpa

- Pressure loss in the heat exchanger 0,2 bar

Operation environment of equipment (ČSN EN 60204-1):

- Min. surrounding temperature – 20°C

- Max. surrounding temperature + 40°C

Electric installation is made according standard ČSN EN 60204-1, covering protection degree IP 54. Equipment GCU-80 is assigned for “NORMAL” locality according sec. 320.N4 ČSN 33 2000-3, mod. IEC 364-3: 1993.

Cooling circuit:

- Compressor MANEUROP MTZ 40 JH 4A VE

- Kind of oil MANEUROP 160 PZ

- Volume of oil 1,12 l

- Kind of the cooling agent R404a

- Volume of cool agent 6 kg

Reviews

There are no reviews yet.