Description

The Draft Beer Tank DBTHI-1000S is a cylindrical pressure container with usable volume 1000 liters for storage and serving of beer. This vessel is mounted on two saddle supports. It is equipped with safety valves and pressure valves.

There are also two glass visors with armored glass for visual inspection of the contents of the tank.

This tank is equipped with insulation and glycol cooling channels. It is designed for cooling by cold water or glycol. For cooling of beer is necessary to connect it to water (or glycol) cooler with cooling medium circulation pump.

Characteristics of BAG IN BOX. beer storage system :

- Beer is storaged in the PE bag which fills all inner space of the tank.

- The bag is exchanged before each filling.

- Sterile bag ensures still a high quality of beer.

- Beer is forced out from the tank by pressed air which acts on the outside of the bag. PE foil works as barrier between air and beer.

- We offer the BEERDRIVE system that is one of the most known bag in tank systems in Europe.

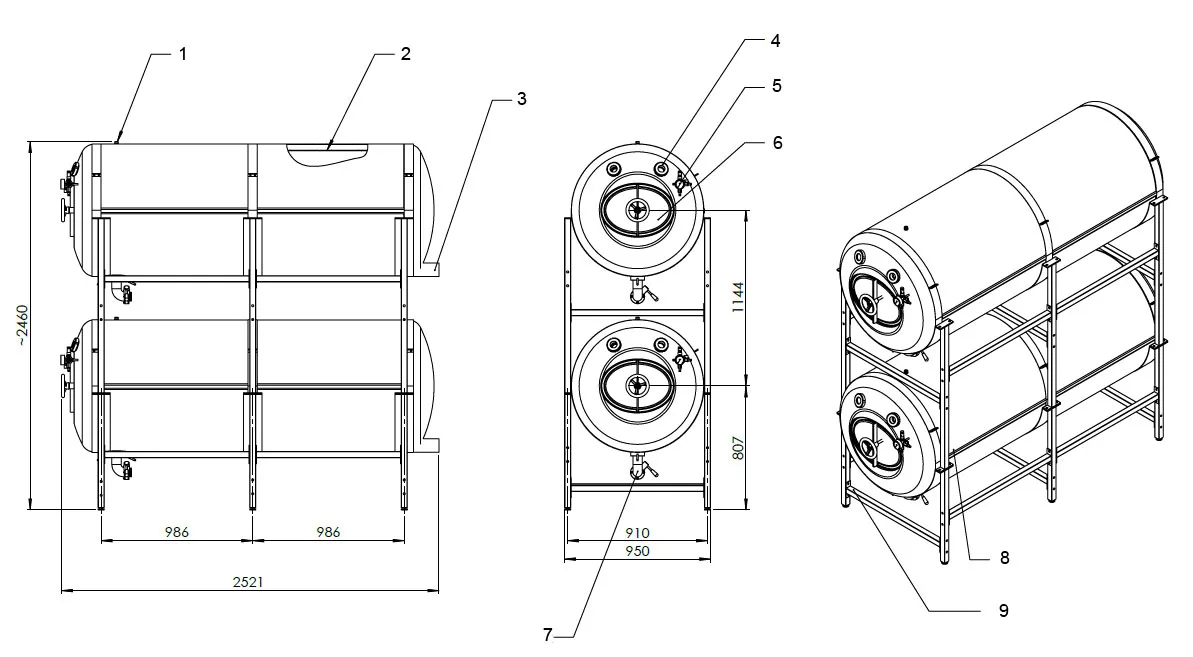

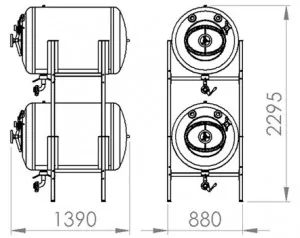

Description of the serving tanks type of DBTHI-1000S (in the configuration : two tanks on top of each other )

- Pressure air inlet ( 5/8″ male)

- Inner tank with a cooling double jacket and insulation

- Cooling water inlet / outlet ( 1/2″ male)

- Inspection sightglass (2 pcs)

- Manometer and safety pressure valve 3 bar

- Insulated manhole with the oval door

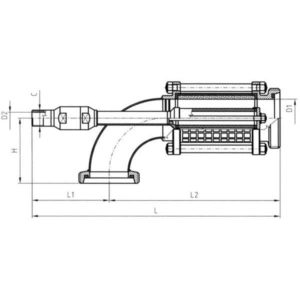

- Insulated filling / draining needle with butterfly valve DIN 11851 DN32 (male)

- Outer jacket – brushed stainless steel

- Stainless steel frame supporting structure

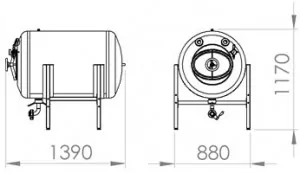

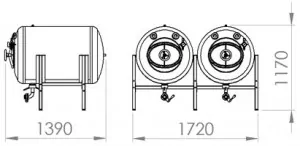

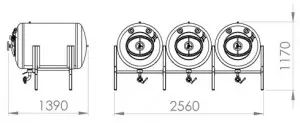

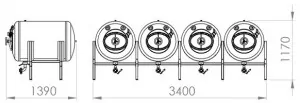

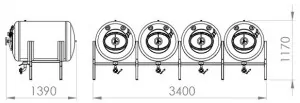

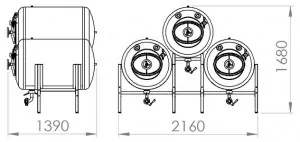

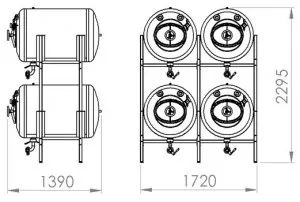

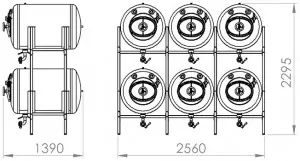

Possible layouts of the DBTHI tanks using support frames :

Technical parameters :

Usable volume … 1000 liters

Total volume … 1020 liters

Highest work overpressure 3 bar

Manufacturing test pressure … 4.5 bar

Highest work temperature … 20°C

Lowest work temperature … 5°C

Work medium … beer, cider, other beverages / air / CO2 / glycol or water

Dimensions (without frames) :

Lenght … 2600 mm

Diameter … 860 mm

Weight … 230 kg

DBTHI-1000S includes in standard :

Draft beer stainless steel tank for 1000 liters of beer (or other beverage) – DOUBLE TANK 2x 500 liters

Cooling channels (duplicators) for cooling medium (water or glycol)

PU insulation

Stainless steel jacket

Manhole with eliptical door

2 pcs glass visors with armored glass

Pipe connections :

- Pipe coupler for output of beer : DN32 DIN11851 (male)

- Pipe coupler for input of pressured air : BSP 5/8″ (male)

- Pipe coupler for input of cooling water : BSP 5/8″ (male) + Reduction for beverage hose D=12.7mm (1/2″)

- Pipe coupler for output of cooling water : BSP 5/8″ (male) + Reduction for beverage hose D=12.7mm (1/2″)

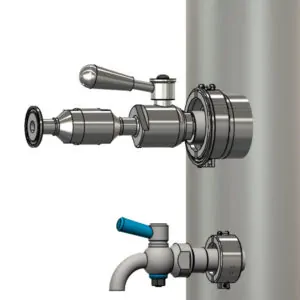

Ovepressure and safety equipment

- distribution cube

- manometer

- safety valve

- shut-off valve

- fill and drain valve with closure flap DN32

Material

Stainless steel for food , resist against sanitizing solutions … AISI 304. We can deliver an European certificates for all materials.

The DBTHI-1000S is a pressure equipment which is manufactured in accordance with the provisions of the Directive of the European Parlament and of the Council of the European Union PED 2014/68/EU (EC).

Gallery :

Reviews

There are no reviews yet.