Description

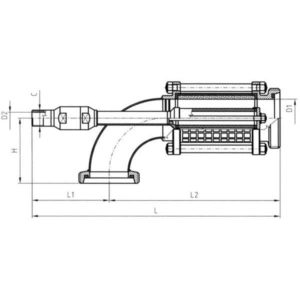

Automatic bottle labelling machine for applying one or two self-adhesive labels (on the same reel)

Fully automatic bottle labelling machine suitable for many types of the cylindrical bottles such as glass bottles, Jam Jars, Spreads, Pickles, Sauces, etc.

The basic machine is suitable for the application of one self-adhesive label on cylindric bottles or front + back label on cylindric bottles from the same reel.

Capacity up to 1000 bottles per hour.

Main properties :

- The bottle labelling station is equipped with a system of rubber rollers which allow a perfect adherence of the label to the rotating bottle.

- A timer device allows the centering of the counter label. This timer is adjustable in order to be able to find the absolute perfect position of the label.

- Labels and counter labels are applied with an extreme simplicity and precision by means of independent heads.

- The machine presents the solutions which better reflect the equirements of precision and practicality, offering automation and technology to the highest standards.

- The machine is compact and robust, designed to be used as an independent equipment . It is suitable also for the insertion in a filling line – the input conveyor and the output conveyor of the bottle can be adapted to various height of the cooperating machines.

- The machine can be adapted to various size bottles and labels.

- The machine is constructed mainly in stainless steel and other anti-corrosive materials in order to guarantee long life with low maintenance operations.

- The machine in the standard configuration is delievered with conveyor and cumulative collection table with motor which is suitable for pulling the complete small filling line conveyor (approx. 5/6 meters) with 3-phase motor 380V-420V 50Hz.

- Optionally the machine can be designed to be supplied with 1-phase 230V / 50Hz voltage (see the optional equipment)

- Hourly production capacity is maximally 1000 bph. Maximal speed depends on number of labels, their size and the shape of the bottle.

- The speed can be adjusted with the application of the timed selection star (see optional).

- The machine is also equipped with safety cabin at EEC norms.

- The basic machine is supplied with 1 labelling station.

Technical parameters :

- Power consumption :

– 0,18 kW for the clamping roller motor

– 0,18 kW for the conveyor drive

– 0,18 kW for each labelling station

– 0,15 kW for the printing unit (if installed) - The basic machine is equipped with drive, 1 station and clamping roller, so the total consumption of the basic machine with one station is 0,54 kW.

- Air consumption 50Nl/min

- Weight : approximally 250kg (according to accessories installed)

- Maximal number of labelling stations : 2

- Collection table on the output : 50 x 40 cm

- Dimensions of the machine on wooden pallet: 190x110x190 cm

- Weight: 250kg.

Optional equipment :

On request the machine can be equipped with:

– Automatic bottle positioning system

– Automatic label or capsule positioning system

– Accessories for the application of the counter label on round bottles

– Other accessories as per optional equipment list.

Price list – standard and optional accessories :

Code |

Description |

Price |

| STANDARD EQUIPMENT | ||

| 35362 | BLA-MB1000 : Automatic bottle labelling machine 1000 bph (one labelling station is included) | On demand |

| OPTIONAL EQUIPMENT | ||

| 21904 | Thermal printer for hot foil : date/batch number (28×18) – Date printing unit (printing area 28×18 mm) – 3 lines | |

| 28021 | Printing date format dd.mm.yyyy – Character set to print date in format dd.mm.yyyy on labels (totally 38 pieces of character stamps) | |

| 34496 | 10 pcs of the Printing ribbon – Roll of the black printing tape for label date/batch printing (price is for 10 rolls) | |

| Total for the whole basic date/batch printing kit | On demand | |

| 25347 | Two labels on the same reel – Device for the application of both the front label and counter label from the same reel. Only for cylindric bottles. (The output capacity of the machine will be reduced when applying two labels on the same bottle) | On demand |

Reviews

There are no reviews yet.