Description

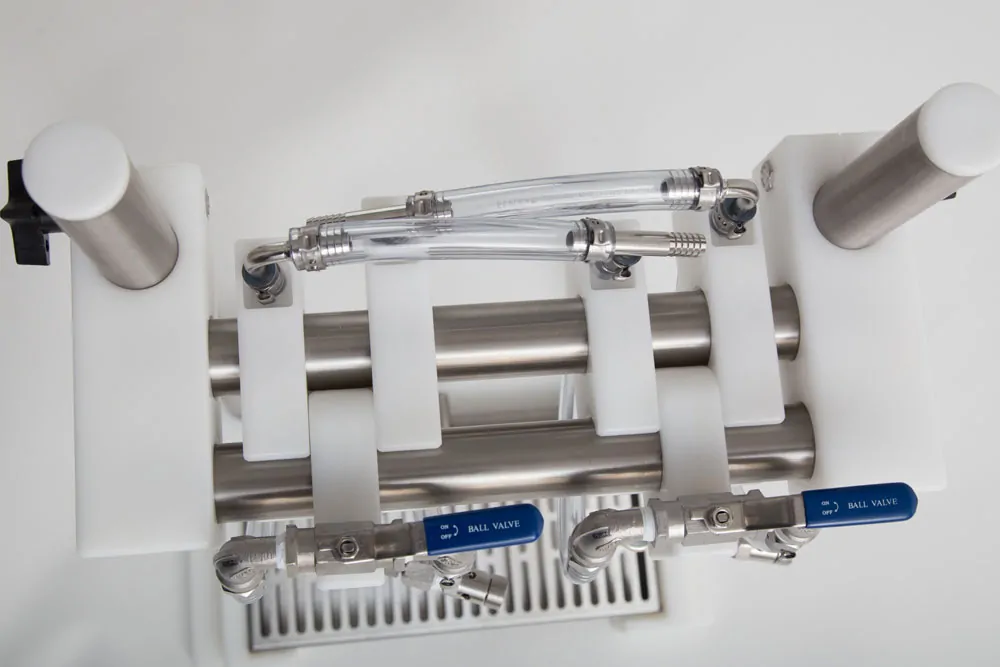

A simple manual isobaric filling mechanism for easy filling of bottles: TwoMan contains of two filling valves and has a simple design. It is suitable for filling sparkling wines, soft drinks, beer, etc., (any kind of bottle such as glass or PET). It is made from stainless steel AISI 304 and an acetal food grade plastic.

Filling capacity (maximum) :

- up to 150 pcs of bottles per hour (for bottles with volume 0.65 liters)

- up to 200 pcs of bottles per hour (for bottles with volume 0.50 liters)

- up to 250 pcs of bottles per hour (for bottles with volume 0.35 liters)

The bottles filling capacity depends on: the quality and pressure of beverage, size of bottles, the ambient temperature, the beverage temperature, the pressure of carbon dioxide, and on user’s experiences.

CHARACTERISTICS:

- Manual isobaric system for the filling of bottles with two universal stainless steel filling heads.

- Stainless steel valves (with three possible positions) to filling bottles with carbon dioxide, to filling bottles with a beverage and the close.

- Stainless steel adjustable pressure valves for fine-tuning fill speeds.

- Easily removable drip tray made of stainless steel with drain pipe for pipe fastening

- Fixing points that allow the unit to be clamped or bolted to the desired surface.

- Beverage and carbon dioxide gas piping with resistant stainless steel forging.

- Attachable to any source of carbonated liquid, gas and cleaning solution that uses many standard fittings.

- Fully adjustable height control to accommodate many different bottle sizes.

- All parts of the unit can be easily disassembled for maintenance work or cleaning.

The equipment has two piped ends with a diameter of 3/8 inch for the feed hose line. One for gas and one for liquid. A user has to connect the piping, clamps and fittings with the output from a pressure tank with a beverage and also with the carbon dioxide bottle.

Recommended dimensions of bottles :

The system can easily handle bottles of 230 mm high and more. Filling of very large bottles, where the needle does not reach the bottom, will require adding a short plastic hose to the end of the needle to get to the bottom of the bottle. This reduces the turbidity during filling and the foaming of the beverage. Filling of bottles smaller than 200 mm height requires the shortening the end of the filling needle.

Dimensions of the filling mechanism :

- Width : 520 mm

- Depth : 230 mm

- Height : 670 mm

- Weight : 8 kg

How the filling mechanism works :

Operation manual to download

Optional accessory :

2 pcs of silicone plugs to filling PET bottles – diameter 18/24mm, inner hole 9mm …… 20 Eur

![]()

Reviews

There are no reviews yet.