Description

Monoblock with automatic rinsing of bottles – isobaric filling of bottles – capping of bottles – electronic valves – type BFA-MB2000

Hourly output: 1200 bph – 1800 bph (cylindrical bottles 0,33 lt *) – The output capacity depends on the type of beer, temperature and pressure.

Further degassing and gas injections will take up more time!

Filling temperature 0°C – 4°C

Stainless Steel AISI 304

Operating cycle:

The bottles on the conveyor belt are separated and placed under pliers. These pliers hold firmly the neck of the bottle. During the rotation the pliers are rotating, too. The bottles are turned downward and placed under double vacuum and high pressure filling machine with eight filling heads.

The bottles on the conveyor belt are separated and lead to an entry star that places them on a stainless surface with a regular and smooth rotary effect.

The pneumatic cylinders lift the bottles and bring them directly under the filling nozzles (by compressed air)

Technical description :

- Rinsing part – nozzles – with nine grippers. The rinsing turret is from stainless steel AISI304. The parts which are in contact with the cleaning fluid are made from AISI 316 while the plastic parts are made from other material. The machine is also equipped with a manual system for adjusting the distance between the pliers and the level at different bottle heights. The movement of the mechanical parts is done by chains made of steel or plastics (noise reduction).

- The basis of the machine is a rigidly welded construction with height-adjustable supports, bending resistant or vibration resistant.

- There is also a support of the main filler, a driving system, a cam for lowering the cylinders for air recuperation, gears that control the input / output stars and the scroll.

- All components can be easily inspected.

- The rotating plate carrying the tank is connected to the machine base by means of a large diameter bearing disc and guided by self-lubricating guide sleeves.

- A cogged wheel driven by a gear motor is fixed on the rotary plate holding the cylinders; the rotary plate is welded to guarantee absolute rigidity.

- The tank is connected to the rotary plate via a manually adjustable height system so that bottles of different sizes can be used despite the limited stroke of the cylinders.

- The height can be adjusted by a small hand-wheel.

- The air recuperation cylinders are raised by compressed air and lowered by a cam.

- The compressed air distribution system is connected to all cylinders and is adjusted with a self-lubricating pressure reducer.

- The isobaric tank is connected to the rotary plate via a manually adjustable height system so that bottles of different sizes can be used despite the limited stroke of the cylinders. The height can be adjusted by means of a small hand-wheel.

- The filling nozzles bolted to the isobaric tank can be easily dismantled.

- On the electrical panel there are low tension push-button control machine and thermal relays.

- In addition, safety switches are placed both on scroll and inlet/outlet stars.

- The cylinders are equipped with a lowering cam so that, after filling, the bottles are mechanically lowered onto the outlet star.

- The pressure tank, made from thick, strong stainless steel, can work at a pressure of six Bar (tested at a pressure of seven Bar in compliance with P.E.D. safety directives). It is complete with a detachable cover (highly polished with mirror type in the inner side.)

- Product Level checkers are located on the pressure receptacle cover.

- On the front side of the tank there is a small inspection window.

- The product source vessel is connected to the central distribution system of the filling part by a feeding pipe which is fitted with an isolating valve.

- Smaller pipes connect the central distribution system to the pressure tank.

- The filling nozzles are fixed to the pressure tank by means of bolts which can be easily dismantled.

- The stainless steel filling nozzles are made specifically for this machine by highly specialized workshops. Perfect sterilization and faultless reliability of the system are guaranteed.

For a correct filling, it is necessary filling the product in a constant manner and under the same pressure!

Filling valve ‘DPS’

The type DPS filling-valve was designed specially for beer, cider + other sparkling beverages that are sensitive to changes of oxygen. It is a double degassing valve that reduces oxygen in the bottle to negligible levels.

Precise valve construction ensures perfect operation even at very high pressure. In case of partial or complete bottle damage, the valve immediately shuts off due to its sensitivity to pressure differences to prevent the spread of compressed gas or liquids.

Automatic crowning turret (one head)

Suitable for crown caps Ø 26 mm on glass bottles.

- Stainless steel cap feeding device with vertical closing

- Outfall

- Device to check presence of crowning caps

- A pressure head that permanently shapes the cap

- Control cam

- Central turret column for installation on the MODULBLOCK

- Shaft (star)

- ten-compartment star

- Reducer

PARAMETERS (bottle) :

Closure: 26mm (crown cap)

Cylindrical glass bottles 330ml

Max diam. 110mm

Height range of bottles 180 – 350mm or 150 – 320mm

TECHNICAL FEATURES:

- Rinsing machine: electrical

- Filling and capping machine: manual – mechanical

- Vacuum pump, rinf type, with small tank in stainless steel AISI 304

- Water nozzle before the capping of bottles

- Lubricator

- Set of adjustable feet with M30 stainless steel

- Standard bottles are moved clockwise. Counterclockwise on request and at extra cost.

- Machine made for one cylindrical bottle diameter, one cap size

- Bottles conveyor (stainless steel aisi 304); standard type section 100*100mm

Waterproof electric panel in stainless steel with low voltage controls, plc, with inverter and display :

PLC, Electromechanics: Telemecanique

Display, inverter: Telemecanique or Siemens

Parameters of usable bottles :

Min /Max diameter of bottle : 55 to 110mm

Min / Max bottle height in standard version: 170 to 340mm

Max height difference between the lowest and the largest bottle: 170mm

Tolerance of the diameter of bottles: +/- 2mm

Process phases:

1) Air degassing from the bottles through the vacuum pump (one or double) ;

2) Bottles pressure compensation by inert gas injections ;

3) Isobaric filling (there is no security wire mesh on this machine) ;

4) Discharge of pressure ;

In the end of the filling cycle, the bottles are transported by the conveyor belt to the front of the machine (to the operator’s side).

Power supply:

Electrical requirements : 7,5 kW 3ph 400 V 50Hz.

Pneumatic : Compressed air 6 bar

Air consumption : 400 Nl with 3/8” female thread – Rilsan pipe 10mm

Water (bar): 3,5 with ½” female thread

CO2/N : cylinder with reducer 2,5 bar with 1/4” inner thread – Rilsan pipe 10mm

Product Connector : DN 32 female thread

CIP Connector : DN 32 female thread

CO2 consumption at 1bar: 2gr./lt. (it depends on the temperature of bottling, pressure and other parameters)

Notes about the electrical power installed:

- 1.5 Kw for main engine

- 0.75 Kw for the conveyor drive

- 3 Kw for the vacuum pump

- 0.18 Kw for the lifting of the rinser

- 1.5 Kw for the management of the pump in the event that the machine has the option to work by gravity

TECHNICAL DATA

– Maximum height : 340-370mm

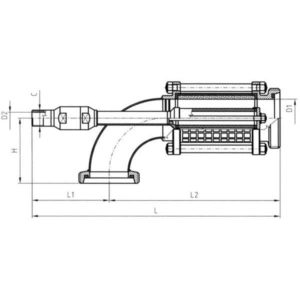

– Machine dimension : cm 300x120x200 h

– Weight Net : 1500 Kg

* Just informative

SAFETY AND STANDARDS

- Complete safety barriers in AISI 304 stainless steel

- Safety guards compliant to CE standards, with opening doors and emergency device to stop the machine when opened

- Safety devices throughout the machine in accordance with CE and Machinery Directives

- Test: ISPESL – PED

- Seals and plastic parts that are in contact with the product are made of material that complies with the relevant directives

Optional accessories :

- Cleaning device when the bottle explodes (Device to clean the filling valve when a bottle explodes) … 2650 Eur

- Photocell for lack of bottles (on inlet) or when it is full of bottles (on outlet) … 650 Eur for each

- CIP Sterilisation Cam (Cam for the cleaning of the Dummy bottles) … 520 Eur

- Dummy bottles with quick release .. 1940 Eur for each filling valves

- Bottle sensor (Microswitch at filler’s exit ) … 920 Eur

- BLA-MB2000 Automatic monoblock bottle labeller … 7900 Eur

Description of accessories :

Cleaning device in case of bottle explosion (bottle 6-20)

Device to clean the filling valve when a bottle explodes

For filling machines with eight – twenty filling valves (not available on six valve fillers)

Photocell

Photocell for lack of bottles (on inlet) OR when the machine is full of bottles (on outlet) – (price each)

Unit price for each photocell

CIP STERILISATION CAM-06-24

It is used for the CIP cleaning of the machine using dummy bottles. This solution is very effective when it comes to thorough cleaning of the machine.It can be done when the machine is in motion and the product passes through all machine circuits (filling valves, tank and piping) – including the vacuum circuit (in case that the machine is equipped with a vacuum circuit and any kind of degassing system – single or double).

The machine must be equipped with dummy bottles without the hole at the bottom when using the vacuum circuit recirculation.

In the case of a machine equipped without degassing, the fake bottles will be equipped with a small hole at the bottom to allow cleaning with the detergent.

The cleaning product is fed to the machine from the machine’s product inlet. With the rotation of the machine the filling valves are opened and the Dummy bottles are consequently filled completely with the sanitizing product.

The special cam on the machine tank will allow all buttons of the valve to open (1, 2 or 3 buttons depending on the valve type). The pressing of the buttons will therefore be done by the cam itself and therefore this will allow the cleaning product to go back from the false bottle through all circuits including the CO2 circuit and out through the vacuum circuit.

In case of machines equipped with degassing, the cleaning product comes out of the vacuum part (which is the point where the vacuum pump is connected). NOTE: It is necessary to install a three-way valve on the vacuum pipe to prevent the cleaning product from returning back to the vacuum tank.

By turning the inlet and outlet of the disinfecting product, it is possible to “backwash”

This system is specially designed for machines with the Double prevacuation (degassing) system (DPS valve), however it can be used also for other versions, providing that the false bottles have the holes on the bottom to discharge the sanitation product.

The system guarantees very good machine cleaning without installing a collector that can not be installed on small machines.

For this solution, the machine must be equipped with fake closed bottles (for all degassing valves) and fake bottles with a hole for other valves.

In case of the “S” valve, the cam is not necessarily requried.

Dummy bottles with quick release

Dummy Bottles with quick release (price per each filling valves)

Bottle sensor

Microswitch at filler’s exit

These devices allow the machine to stop and go into emergency when a bottle is jammed at the exit of the filling part. Prevents bottle damage and damage to parts of the machine.

Reviews

There are no reviews yet.